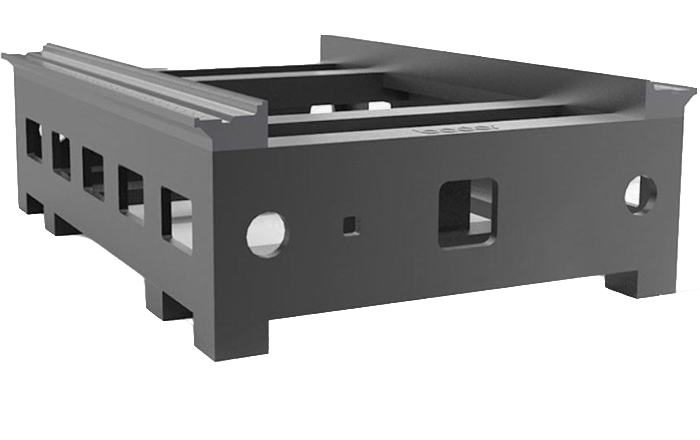

Lathe machine series BL-H50T. Models: H50T/TC/TY.

BL-H50T (TCTY) is a lathe machine designed for machining metal and non-metal products. It features high productivity and precision, allowing for the easy execution of complex tasks.

Equipped with advanced technologies, the BL-H50T (TCTY) offers high speed and cutting depth, ensuring fast and efficient operation. The machine is also equipped with a cooling system that prevents overheating and ensures a long service life.

The BL-H50T (TCTY) has a compact design, making it an ideal choice for small manufacturing spaces. It is easy to operate and maintain, which helps save time and increase productivity.

Moreover, the BL-H50T (TCTY) provides high machining accuracy, allowing for the production of items with a high degree of precision and surface smoothness. This is especially important in the manufacturing of metal products, where even minor inaccuracies can affect the quality and strength of the item.

All these features make the BL-H50T (TCTY) lathe machine an ideal choice for manufacturing enterprises seeking reliable and high-quality equipment for machining metal and non-metal products.