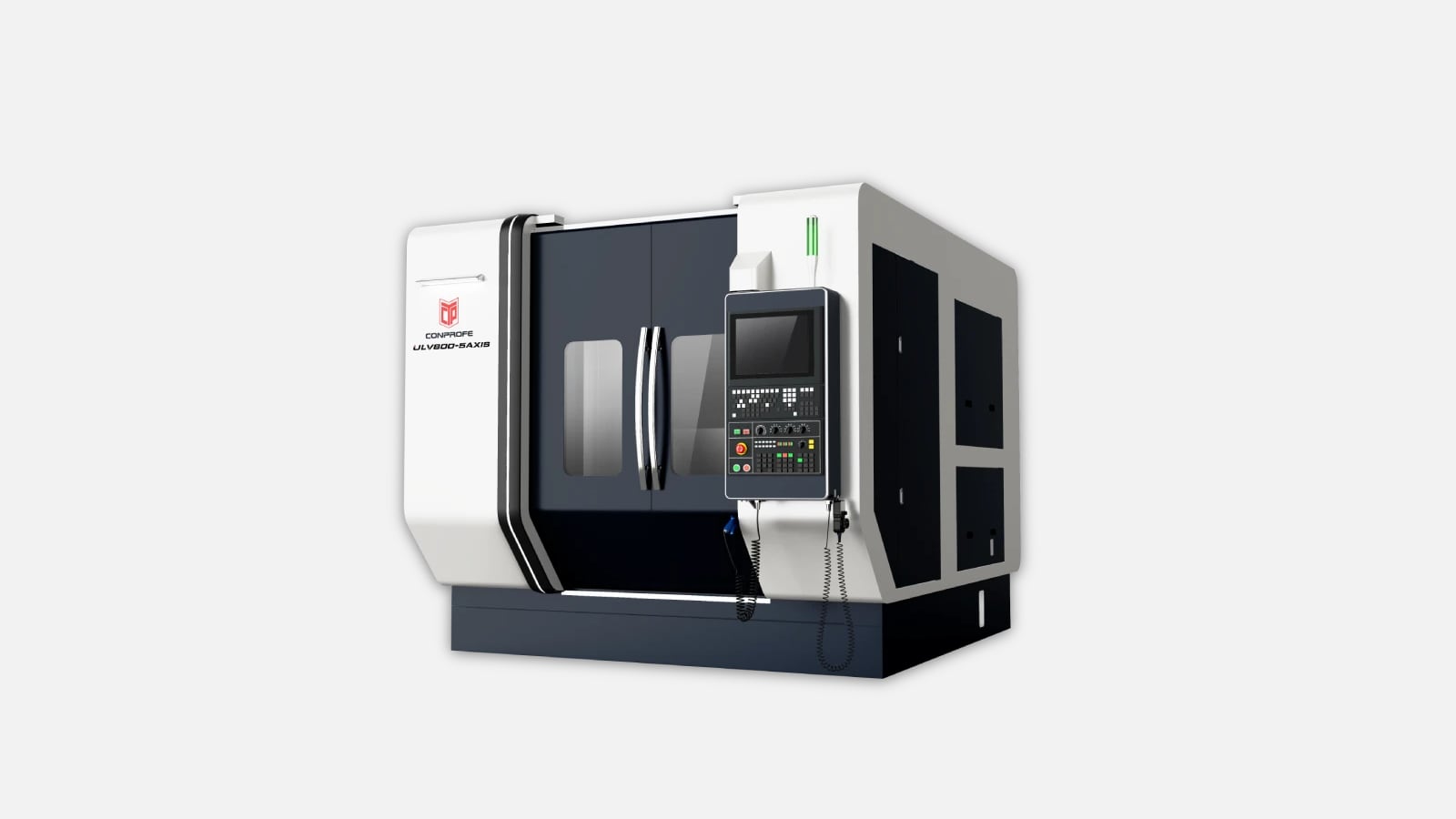

CNC Machining Center ULV-800 from CONPROFE

CNC Machining Center ULV-800 from CONPROFE

Ultra-precision CNC machining center with 5 axes ULV-800.

Ultrasonic CNC Machining Center UHB-600 from COMPROFE

Ultrasonic CNC Machining Center UHB-600 from COMPROFE

Ultrasound Processing Center COMPROFE with CNC – UHB-600. 3 axes.

CONPROFE was founded in 2003 in Guangzhou, China, and quickly became known for its ultrasonic machining technology aimed at hard-to-cut materials such as aerospace alloys, ceramics, and carbon fiber reinforced polymers. Company brochures for 2023 mention more than 700 employees and a portfolio of over 60 CNC models, ranging from 3-axis vertical mills to full 5-axis ultrasonic machining centers.

“Our goal is to enable fluid-free precision machining that respects both productivity and the environment,” — CONPROFE Technical White-paper 2022.

The firm ships roughly 350 machines per year to Europe, North America, and Asia, according to customs data aggregated by ImportGenius. Customers appreciate the combination of ultrasonic vibration, near-dry Minimum Quantity Lubrication (MQL), and classical chip removal features found in mainstream VMCs, so integration into existing workshops is straightforward.

Ultrasonic machining superimposes high-frequency vibration onto the tool. The vibration amplitude is typically 8–15 µm at 20–40 kHz. This micro-oscillation repeatedly disrupts the chip formation zone, lowering cutting force by up to 40 % — a figure confirmed by a 2021 peer-reviewed study in the Journal of Manufacturing Processes. Lower force means thinner burrs, reduced tool deflection, and the possibility to machine brittle materials without cracks.

Before diving into the specification table, it helps to understand how CONPROFE structures its range.

Each family shares a Siemens or Heidenhain control skeleton, making operator training painless for shops already running European CNCs. A service bulletin from Siemens (ID 109770236) confirms native support for the ultrasonic add-on, so no external generator box clutters the electrical cabinet.

The table below summarises three representative machines. Figures come from the official 2023 catalogue.

The next two sentences prepare you for the numbers and highlight why they matter. When comparing units, pay attention to power density and rotary table accuracy, because those parameters explain the pricing tiers.

| Model | X/Y/Z travel, mm | Spindle power, kW | Max RPM | Rotary table dia, mm | Positioning accuracy, µm |

|---|---|---|---|---|---|

| H500 | 500/450/400 | 15 | 15000 | — | ±5 |

| U600 | 600/550/450 | 18 + ultrasonic | 24000 | 400 | ±4 |

| U-D1100 | 1100/900/600 | 26 + ultrasonic | 24000 | 630 | ±3 |

Knowing these values helps owners match machine size to part envelope and tolerance targets. Keep in mind that the ultrasonic spindle shows two power ratings: conventional S1 power and a slightly lower continuous rating when vibration is active, a common trait among all brands that incorporate piezo stacks.

Two or three sentences are needed before the list to set the context. Traditional flood coolant management is expensive because of disposal fees and health regulations. CONPROFE’s near-dry system delivers a fine oil-air mist right at the cutting edge.

Because the mist is consumed during cutting, sump maintenance becomes as easy as wiping the machine base once per shift.

Many European plants already evaluate brands such as DMG MORI LASERTEC D, Makino Ultrasonic, and Roeders RXP-U. Understanding how CONPROFE stacks up promotes informed purchasing.

Although European badges still carry strong brand recognition, the empirical data show that surface finish Ra and cycle times achieved on Inconel 718 turbocharger housings differ by less than 3 % among all four brands when using identical Sandvik Coromant tooling (test report, Fraunhofer IPT, 2022).

CONPROFE machines ship with a two-day on-site application package. The first day focuses on geometric alignment and ball-bar verification, the second on parameter tuning for ultrasonic modes. Operators usually master the G05.2 “ultra” cycle within a single shift, as confirmed by interviews on the Practical Machinist forum.

A short explanation prepares you for the checklist. Piezo ceramics are durable, but they do degrade after roughly 12 000 spindle hours, so preventive maintenance is smart.

Sticking to this schedule keeps vibration amplitude steady, preventing premature tool edge chipping.

Post-processing is available for Siemens ShopMill, NX CAM, and hyperMILL. An optional AI-based chatter detection module was released in 2022. According to beta testers at a Czech medical implant shop, the module cut tool breakage by 17 % during titanium cup milling.

Numerical examples often clarify the business case. Suppose a plant runs 1 000 hours per month on ceramic matrix composites. Switching from flood coolant to near-dry reduces fluid spend by about €0.80 per hour. At that duty cycle, the coolant module alone pays for itself in under 10 months.

Over 1 600 CONPROFE units have been delivered worldwide, with 540 installed in Europe, including tier-1 automotive suppliers and a British Formula E powertrain lab. Certification to ISO 14001 supports bids in industries where sustainability metrics are audited.

While remaining conservative with marketing promises, the company disclosed in a January 2024 press release its plan to release a hybrid laser-ultrasonic platform. No release date has been set, but beta machines are already cutting carbon fiber wings in a Spanish aerospace plant, according to trade journal CompositesWorld.

CONPROFE provides a solid mix of ultrasonic know-how, fluid-free machining, and familiar European controls. The blend attracts precision job shops, aerospace subcontractors, and medical implant houses that seek tighter tolerances on hard materials without degrading shop hygiene.

In summary, the brand offers professional CNC equipment that reduces cutting force, cuts coolant bills, and simplifies environmental compliance. Those attributes explain why a growing number of European firms add the U Series to fleets that once consisted solely of domestic or Japanese machines.