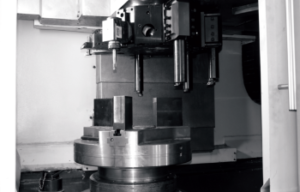

Alpha V7L Lite Machining Center by PRIMINER

Alpha V7L Lite Machining Center by PRIMINER

Processing center Alpha V7L Lite with 3 axes.

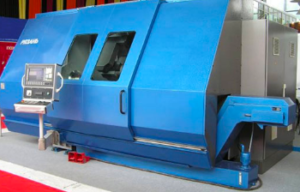

BL-CK75 BLIN Series Lathe for Heavy Machining

BL-CK75 BLIN Series Lathe for Heavy Machining

Lathes with inclined bed series BL-CK. Models: CK7516A, CK7520A, CK7525A, CK7530, CK7550.

BL-S205 Series Turning Machining Centers

BL-S205 Series Turning Machining Centers

Precision Series Processing Centers BL-S205.

Models: BL-S205, BL-S205M, BL-S205Y, BL-S205S, BL-S205SM, BL-S205SY.

BLIN precision lathes of the BL-SK series

BLIN precision lathes of the BL-SK series

Lathes with an inclined bed, precision series BL-SK40S/50S/66Q.

BLIN standard series BL-CAK lathes

BLIN standard series BL-CAK lathes

BLIN lathes with a flat bed. Models: BL-CAK6140, BL-CAK6150, BL-CAK6161, BL-CAK6166, BL-CAK6180.

CNC (Computer Numerical Control) machining centers are modern, high-tech machines specifically designed to automate and optimize the processing of various materials. These centers combine the functions of milling, turning, and drilling machines, allowing for complex machining operations to be performed with high precision and efficiency.

One of the key features of CNC machining centers is their ability to operate based on pre-programmed instructions, enabling a wide range of operations to be performed automatically without the need for constant operator presence. This significantly increases productivity and reduces the likelihood of errors, which is especially important when processing complex parts requiring high precision.

CNC machining centers can be utilized across various industries, including machining, aerospace, medicine, electronics, and more. They can work with different materials such as metals, plastics, wood, and composite materials, creating intricate parts and components with a high degree of accuracy and repeatability.

The benefits of using CNC machining centers include:

– High precision and repeatability: CNC technology achieves a high level of accuracy and consistency when machining parts, which is crucial for producing complex and demanding products.

– Increased productivity: Automatic operation based on pre-defined programs reduces processing time and enhances productivity.

– Flexibility and versatility: CNC machining centers offer a wide range of capabilities and can perform various machining operations, making them versatile and flexible tools for different tasks.

– Reduction of errors and cost savings: Automating the machining process with CNC minimizes the risk of errors and reduces labor costs and material waste.

Our range includes various models of CNC machining centers, from compact and economical options for small-scale production to professional, powerful machines for industrial enterprises. We guarantee the high quality and reliability of our products, as well as provide complete technical support and consultations to help you choose the most suitable model for your needs.

CNC machining centers are a reliable and efficient solution for automating and optimizing material processing. Take advantage of modern technology and enhance the efficiency of your production with our CNC machining centers.