Amada — VENTIS-AJe

Amada — VENTIS-AJe

VENTIS-AJe 4 kW fiber laser cuts 25 mm steel with Locus Beam Control and 170 m/min rapids, fit for UAE job shops.

BL-CK75 BLIN Series Lathe for Heavy Machining

BL-CK75 BLIN Series Lathe for Heavy Machining

Lathes with inclined bed series BL-CK. Models: CK7516A, CK7520A, CK7525A, CK7530, CK7550.

BLIN precision lathes of the BL-SK series

BLIN precision lathes of the BL-SK series

Lathes with an inclined bed, precision series BL-SK40S/50S/66Q.

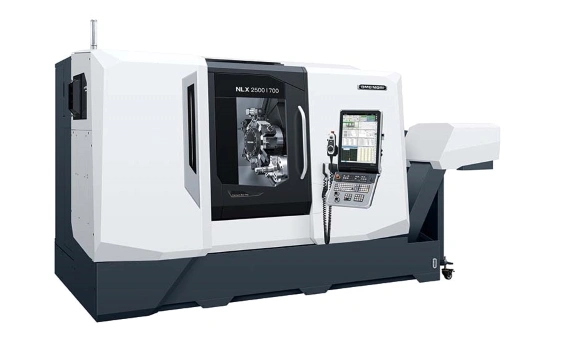

DMG Mori Seiki – NLX 2500 Universal Turning Center

DMG Mori Seiki – NLX 2500 Universal Turning Center

NLX 2500: rigid Y-axis lathe, 80 mm bar through, torque-rich 26 kW spindle, fit for diverse UAE job shops

FANUC — ROBODRILL α-D21LiB5 ADV Plus

FANUC — ROBODRILL α-D21LiB5 ADV Plus

Compact BT30 mill, 24k rpm spindle and 700 mm X travel for speedy UAE job shops.

Heavy Series BL-CKL BLIN Lathes

Heavy Series BL-CKL BLIN Lathes

Lathes with a straight bed of the BL-CKL series. Models: BL-CKL6163, BL-CKL6180A, BL-CKL6180B, BL-CKL61100.

Heavy Series BL-CKW BLIN Lathes

Heavy Series BL-CKW BLIN Lathes

Lathes with a flat bed of the BL-CKW series. Models: BL-CKW61125, BL-CKW61140, BL-CKW61160, BL-CKW61180, BL-CKW61200.

Heavy Series QK BLIN Pipe Turning and Threading Machine

Heavy Series QK BLIN Pipe Turning and Threading Machine

Heavy series with CNC. Models: BL-QK1327B, BL-QK1332, BL-QK1338, BL-QK1343, BL-QK1350, BL-QK1363.

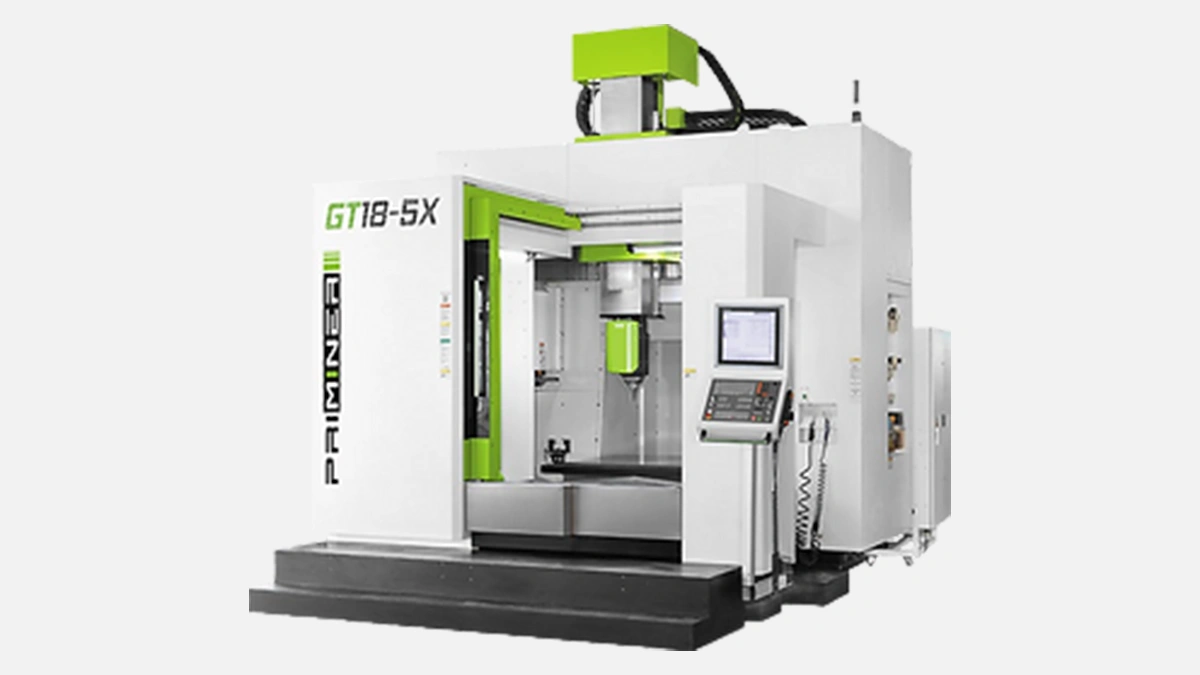

Priminer — GT18-5X

Priminer — GT18-5X

Priminer GT18-5X five-axis center, 650 × 550 × 500 mm travels, 15000 rpm spindle, solid for UAE heat.

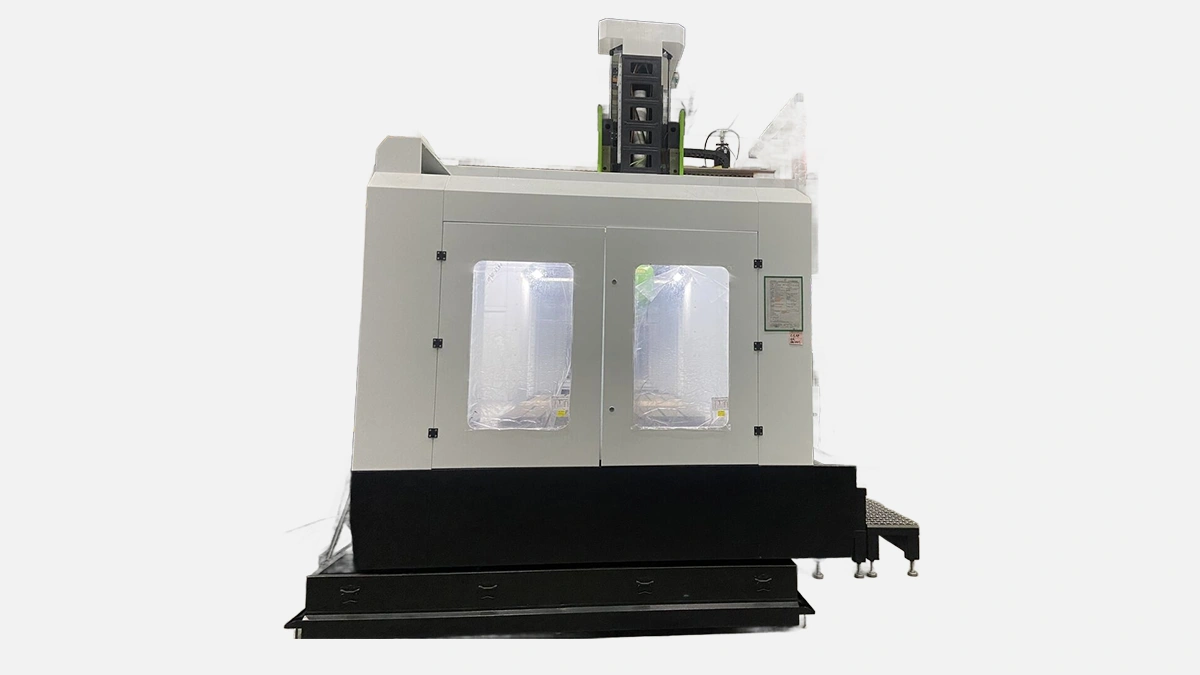

Priminer — GT320-5X

Priminer — GT320-5X

Compact 5-axis center with 320 mm trunnion, 12 000 rpm spindle, built for tight UAE shop floors.

SMEC — SL2000 / SL2000M Slant Bed CNC Lathe

SMEC — SL2000 / SL2000M Slant Bed CNC Lathe

Slant bed 10-inch CNC lathe, 360×560 mm, 3500 rpm spindle, live-tool option.

Standard Series QK Pipe Threading Lathe Machine

Standard Series QK Pipe Threading Lathe Machine

Standard series BL-QK1313, BL-QK1319, BL-QK1322, BL-QK1325, BL-QK1327A.

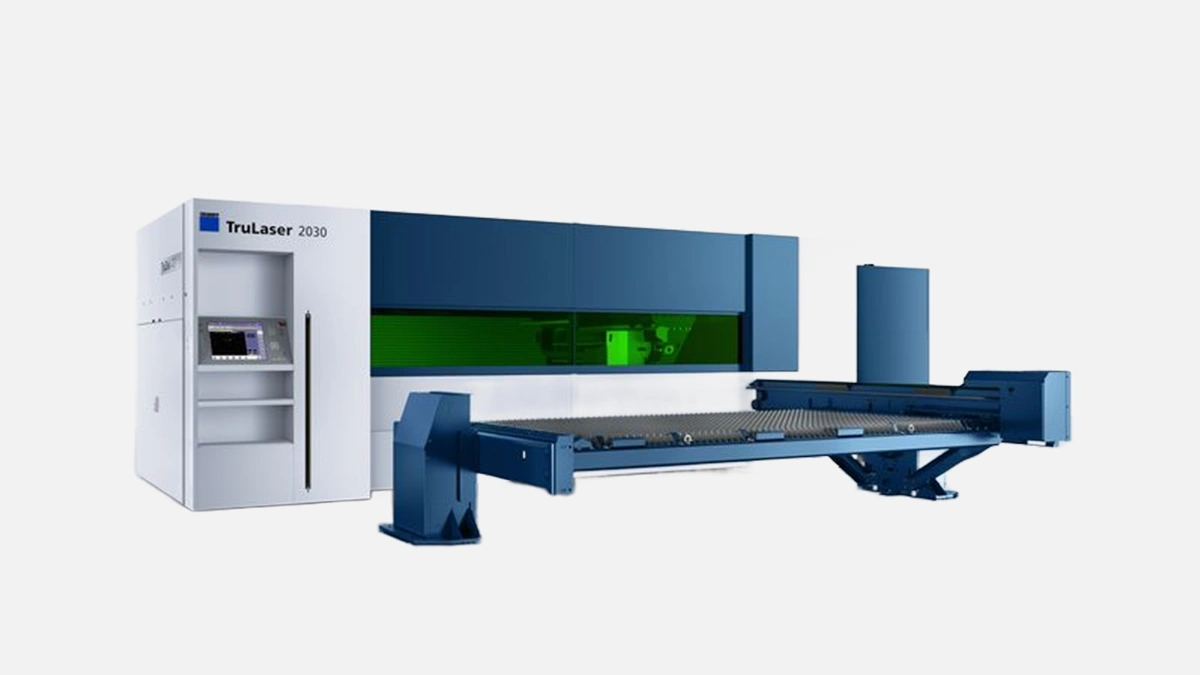

Trumpf — TruLaser 2030 fiber

Trumpf — TruLaser 2030 fiber

Trumpf TruLaser 2030 fiber cuts 3000×1500 mm sheets up to 20 mm thick with 4 kW power, ideal for UAE job shops.

CNC metalworking machines are a modern and efficient solution for processing metal products. CNC (computer numerical control) allows for the automation of the machining process, providing high precision and repeatability of operations. This category features various models of CNC machines that differ in their characteristics and functionality to meet the needs of the most demanding manufacturers.

One of the main advantages of CNC metalworking machines is their versatility. They are capable of performing a wide range of operations, such as milling, drilling, cutting, and engraving. As a result, manufacturers can process various types of metals, including steel, aluminum, brass, and titanium, with high precision and quality.

Each model of CNC machine has its own features and benefits. Some machines offer a large working space, allowing for the processing of large parts, while others have high speed and accuracy, which is especially important for the production of complex and detailed products. Additionally, some machines are equipped with automatic tool changers, which reduces setup time and increases productivity.

All CNC metalworking machines presented in this category are produced by leading global manufacturers, ensuring high quality and reliability. They are equipped with modern control systems that provide ease of use and programming. As a result, even inexperienced operators can quickly learn to work with these machines.

CNC metalworking machines are a reliable and effective solution for manufacturers looking to increase productivity and the quality of their products. With automation and precision in operations, these machines help to reduce processing time and minimize errors. By choosing a CNC machine from our category, you are acquiring reliable equipment that will help you achieve success in your manufacturing.