Alpha V7L Lite Machining Center by PRIMINER

Alpha V7L Lite Machining Center by PRIMINER

Processing center Alpha V7L Lite with 3 axes.

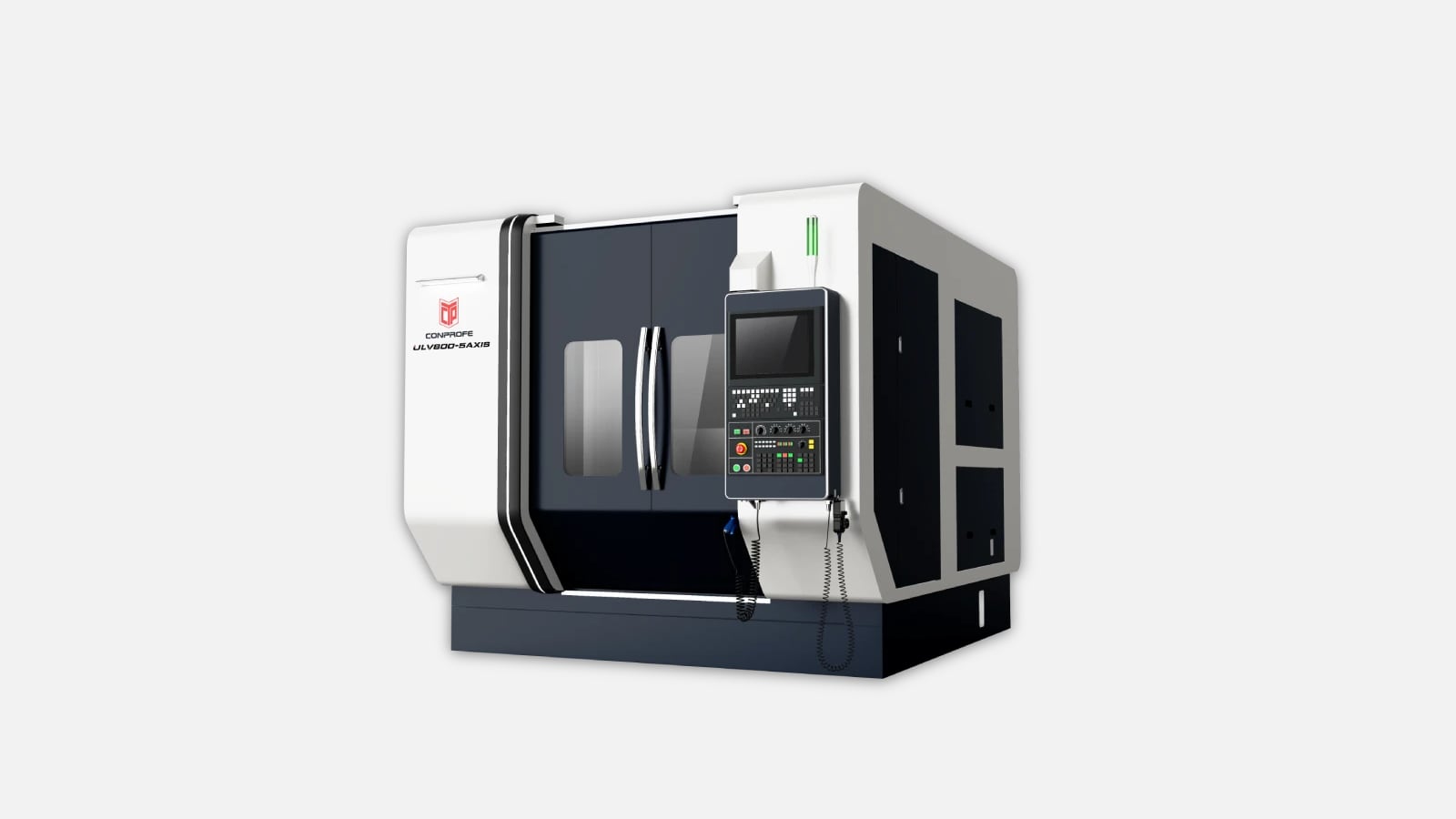

CNC Machining Center ULV-800 from CONPROFE

CNC Machining Center ULV-800 from CONPROFE

Ultra-precision CNC machining center with 5 axes ULV-800.

CNC Milling Machining Center BLIN BL-B850

CNC Milling Machining Center BLIN BL-B850

BLIN heavy series milling machining center BL-B850 with CNC.

Conprofe — MUE-500B

Conprofe — MUE-500B

MUE-500B: 5-axis ultrasonic center, cuts ceramics & Ti fast, low coolant use, fits standard 400 V lines

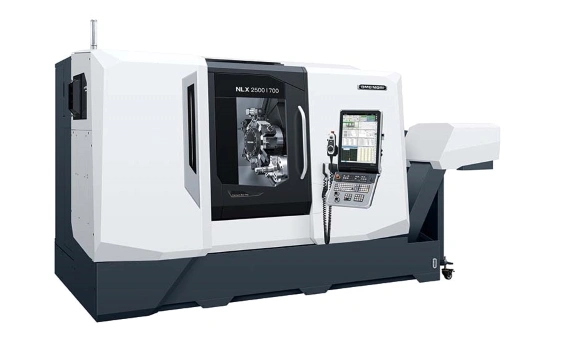

DMG Mori Seiki – NLX 2500 Universal Turning Center

DMG Mori Seiki – NLX 2500 Universal Turning Center

NLX 2500: rigid Y-axis lathe, 80 mm bar through, torque-rich 26 kW spindle, fit for diverse UAE job shops

CNC (Computer Numerical Control) milling machines represent an innovative solution in the field of metalworking. These machines combine high precision and efficiency, allowing for the execution of complex material processing operations with minimal effort.

One of the main features of CNC milling machines is the ability to automate the processing control. With pre-programmed instructions, the machines perform various operations such as milling, drilling, cutting, and engraving with a high degree of accuracy and repeatability. This reduces processing time and improves the quality of the final product.

CNC milling machines are available in various configurations and sizes, allowing for the selection of the optimal solution for specific production needs. They can be used across various industries, including machine engineering, automotive, electronics, and many others.

The advantages of CNC milling machines include:

1. High Precision: The CNC system ensures high processing accuracy, allowing for parts to be produced with minimal deviations from the specified parameters.

2. Flexibility: Due to the capability of programmed control, CNC milling machines can perform various operations and process different materials, making them a versatile solution for diverse tasks.

3. Time and Resource Savings: The automated processing reduces the time required for operations and minimizes the number of defective products.

4. Enhanced Productivity: CNC milling machines enable high productivity due to their ability to operate continuously and at high processing speeds.

5. Ease of Use: With an intuitive interface and simple programming, CNC milling machines are easily mastered even by inexperienced operators.

Our category of CNC milling machines offers a wide selection of models, from compact machines for small productions to large industrial systems. We guarantee the high quality and reliability of each product and provide complete technical support and consultation for selecting the optimal solution for your needs. Contact us today and enhance your production efficiency with CNC milling machines.