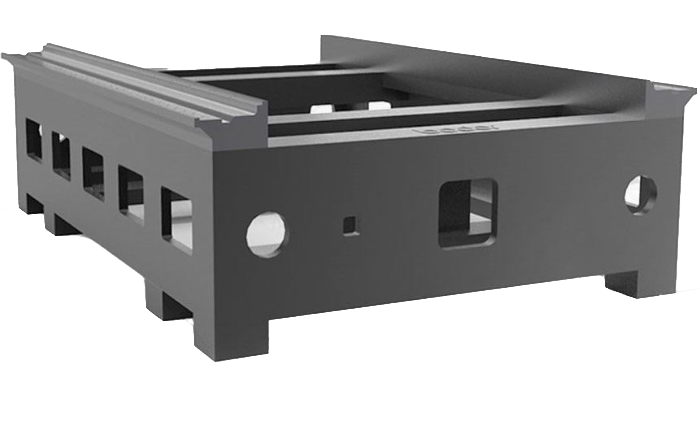

Milling machining center BLIN BL-VL350.

The milling machine model BL-VL350 is a reliable and efficient piece of equipment for processing various materials, including wood, metal, plastic, and more. It is equipped with a high-quality spindle that ensures high precision and processing speed.

One of the main features of the BL-VL350 machine is its compactness and power. It easily fits into small workshops, yet it has sufficient performance for working with various materials. The machine can be used for both industrial production and individual use.

The BL-VL350 machine has many functions that allow you to customize processing to specific needs. In particular, it can perform milling, engraving, cutting, and other types of processing. Because of this, the machine is well-suited for producing a variety of products, from furniture to metal parts.

The BL-VL350 machine boasts high processing precision, which allows for the creation of high-quality and accurate products. Additionally, it has a reliable construction, which increases its durability and reliability in operation.

Overall, the BL-VL350 milling machine is excellent equipment for small and medium-sized productions, as well as for individual use in a home workshop. It features high performance, precision, and reliability, enabling the production of high-quality products of any complexity.