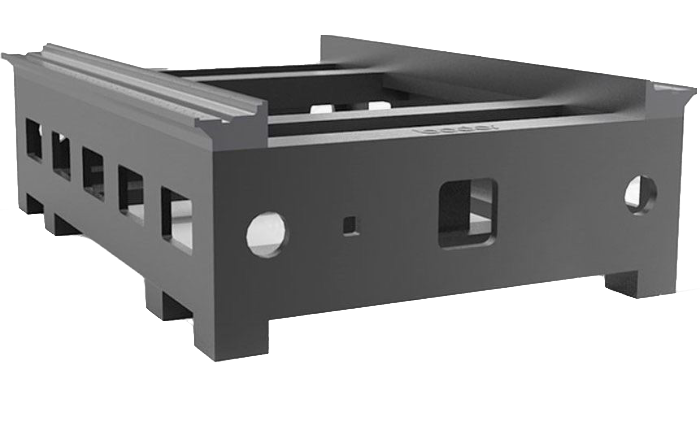

Milling Machining Center BLIN BL-Y1050.

BL-Y1050 is a milling machine designed for high-precision work with metal parts. It features high performance and accuracy, and its compact size allows it to be used in spaces with limited room.

The main advantage of the BL-Y1050 model is its high processing speed. This machine allows for fast and efficient machining of metal parts of varying complexity. With this machine, you can significantly reduce production time and increase your profits.

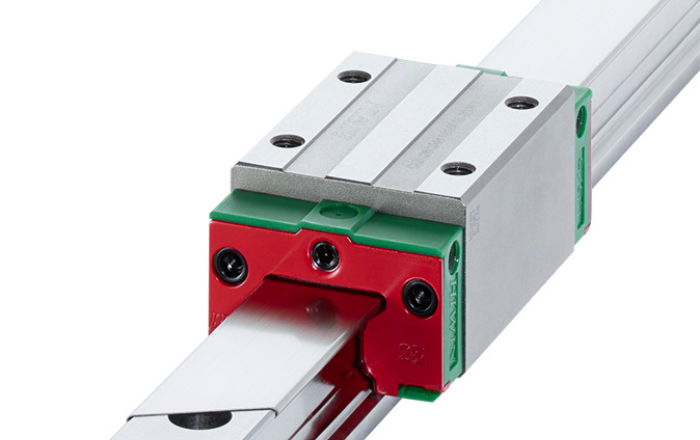

Another advantage of the BL-Y1050 model is its high accuracy. The machine delivers precise machining, enabling the production of parts with a high degree of accuracy. This is particularly important for manufacturing metal components that require exact dimensions and shapes.

The BL-Y1050 model also features a user-friendly and straightforward interface. It is equipped with a modern control system that allows for quick and easy adjustment of processing parameters. This enables operators to use the machine with maximum efficiency and precision.

Finally, the BL-Y1050 model is a reliable and sturdy machine that ensures durability and dependable operation. It is made from high-quality materials that guarantee its longevity and reliability. With this machine, you can be confident that it will serve you well for a long time and provide high-quality machining of metal parts.