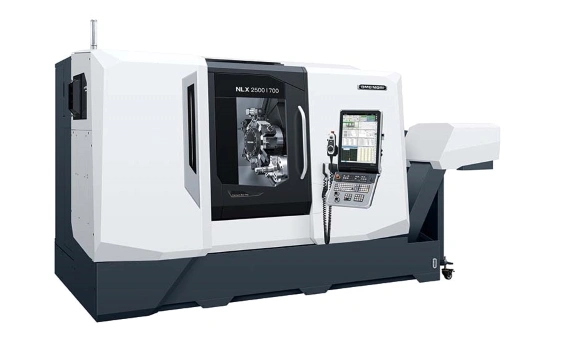

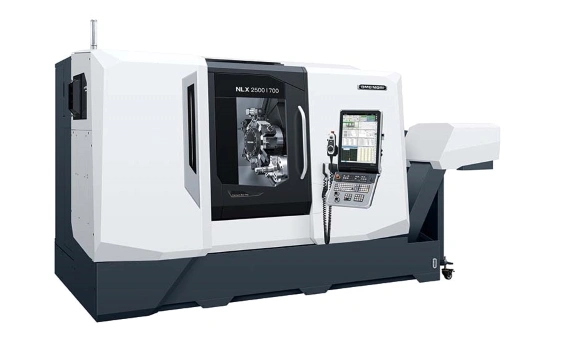

NLX 2500: rigid Y-axis lathe, 80 mm bar through, torque-rich 26 kW spindle, fit for diverse UAE job shops

Short burst first. Metal chips flying. Smell of coolant, unmistakable. DMG Mori pitched the NLX 2500 as a do-it-all lathe, yeah, but when you actually stand next to the sheet-metal you realise the bed is thicker than your arm, table vibration feels almost muted, and the hydraulic chuck snaps shut with a confident thud that every operator in Sharjah likes to hear. Then you look at the control, CELOS on a bright panel, friendly icons, while the old hands keep calling it MAPPS out of habit. Whatever, it boots in 14 seconds, I timed it with my phone, could be plus minus 2 because I got distracted.

So, why bother writing another long rant about yet another Japanese lathe, plenty of those around, right. Thing is, shops in Dubai Industrial City keep nudging me for feedback, they want something rigid enough for API threads one day and some decorative brass knob the next. NLX 2500 fits that odd request, mainly thanks to the mix of travel, through-spindle bar and the optional Y axis slide stacked on the saddle. But I am getting ahead of myself.

The casting is a single piece, no bolted add-ons. Its footprint looks compact on paper yet watch out, the electric cabinet sticks out at the back so leave at least 600 mm clearance or the maintenance crew will curse you. DMG Mori claims they sell roughly 1800 units of the NLX family each year worldwide, and three revisions of the 2500 frame hit the market since 2012. First gen had Turcite on the slideways, second ditched that and went full roller guide, the current version keeps roller guides but adds linear scale feedback as standard, nice touch when you chase micron fits under Dubai heat.

Before probing deeper, a quick table, because spreadsheets people love them. But do not stare at the digits alone, read the comments after, context matters.

| Axis | Travel | Rapid | Drive type |

|---|---|---|---|

| X | 260 mm | 30 m/min | Roller guide |

| Z | 790 mm | 30 m/min | Roller guide |

| Y | 100 mm total | 24 m/min | Box-in-box slide |

Numbers are bold, yeah, eye catching, yet meaningless unless you picture the typical EN24 steel shaft everyone in Mussafah seems to run. You clock roughing passes at 1.5 mm depth with CNMG-12, spindle sits at 750 rpm, torque curve stays flat, chips curl black-blue. At that moment the X axis only moves 0.9 mm per turn, so the 30 m/min claim is far away, but rigidity is right there, you feel it on the insert nose, no chatter.

The main spindle on the NLX 2500|700 spins up to 4000 rpm, hole through 112 mm, straight shot bar feed up to 80 mm, nice match for most stock delivered by Ajman Service Center trucks. Power rating says 26 kW at 10 % duty, drops to 22 kW in continuous mode. Torque peak is 788 Nm below 700 rpm. That last number sounds dry but picture cutting a stub ACME thread for an oilfield hanger, tool pressure goes crazy, the motor barely groans. Cooling jacket around the stator helps because ambient in July reaches 45 °C inside shops that skip AC.

There is a sub spindle option, yes, but universal configuration in UAE usually ships without it to shave lead time. Fine by me, fewer moving parts, easier to align Swiss bar feeder later.

CELOS interface feels like someone glued smartphone icons over the old MAPPS menu, some love it, others switch straight to list mode and forget it exists. Either way, Fanuc macro B compatibility is there, so your dusty parametric programs port across in a day. Ethernet link is 1 Gb, yet the copy speed stalls at 35 MB/s due to old SSD, still faster than sneaking in with a USB drive while the foreman is not watching.

I tossed three test blanks, typical spec from local jobs.

Setup lasted 17 minutes including chuck jaws change, Y axis zero, probe run. Rough and finish combined cycle gave 11.6 minutes on the first part, which is roughly 8 % faster than the old PUMA 300 in the next bay. Chips did not birdnest, conveyors proved okay, only had to adjust washer nozzle angle. For Ali at the night shift that alone is a win, he hates pulling chip balls with a hook.

I promised earlier to put NLX next to other lathes because buyers always crosscheck Mazak and Doosan.

Mazak QTN 250-II

– Similar swing, a bit shorter Z, spindle through 77** mm only, saves space, yet limits bar, Mazak wins on conversational Mazatrol ease but loses on raw torque.

Doosan PUMA 2600 LSY

– Longer bed, same 12 station turret, price list slightly lower, but coolant tank tiny, we kept refilling every second day, NLX coolant capacity 330 L lasts a week, less downtime.

Haas ST-30Y

– Cheap entry cost, US parts, yet rapids at 18** m/min, chip conveyor optional, local resellers in UAE carry fewer spares, waiting time hurts.

So, NLX sits middle in price, top in spindle torque, and second in bar capacity. That combination explains why many Abu Dhabi oil sub-contractors pick it.

NLX 2500 comes in three bed lengths: |500|, |700| and |1250|. Same headstock casting, different saddle stroke. Shops making long valve stems grab the |1250|, but be warned, that pushes machine weight beyond 9.5 t, freight cost up. The shorter |500| saves floor, yet you lose Y drilling reach on long parts. My sweet spot remains the |700|.

I am lazy with grease lines, luckily the lube unit here is automatic, refills every 1500 cycle lines, you just top a 2 kg cartridge monthly. The hydraulic pack sits left side, temperature controlled, alarm pops at 55 °C, never got that high even during August, fan ramps loud though.

A little list of everyday checks, because I forget otherwise.

Do those three and the service guy might never visit.

Dubai free zones push quick deliveries, one-off prototypes pop daily, then vanish, replaced by bulk work for ADNOC. NLX 2500 adapts, not because of marketing slogans, rather the blend of Y axis and a genuine 80 mm bar means you skip second ops. Turn, drill off center, mill a slot, cut off, part exits done, courier picks up before sunset. Shops bill extra margin for the saved setup, profit jumps quietly.

I like the spindle power, yet the turret indexing feels slower than brochure claims, measured 0.26 sec tool to tool, brochure says 0.2. Could be my air pressure, could be the stopwatch lag, still, that half a tenth bugs me. Also, the sheet metal door window scratches fast, DMG Mori sells hard-coated replacement, pricey. Small stuff, yet real.

Enough rambling. NLX 2500 keeps landing on shop floors from Al Ain to Ras Al Khaimah for one simple reason: it just covers most mid-size turning chores without drama. You push heavy API threads, it handles torque, you switch to light aluminium, spindle ramps fast. And if someday you win a job for 3000 pieces of the same flange, robot loader bolts right on, DMG Mori sells it under the Robo2Go name, wiring already pre-installed.

So, companies that juggle oilfield fittings, food-grade stainless hubs, and occasional aerospace bracket all within the same week usually end up with NLX. That blend of rigidity, Y axis reach, and respectable bar capacity simply ticks many boxes for Gulf shops.