DYNOMAX 1500brd 2WD BRAKED dyno handles up to 1250 hp and 300 kph, perfect for UAE tuning shops.

The DYNOMAX 1500brd 2WD BRAKED is a floor-mounted chassis dynamometer engineered for professional tuning shops that specialise in high-output rear-wheel-drive and front-wheel-drive cars. It combines an inertial drum with an electromagnetic brake, giving you the freedom to run purely inertial sweeps for quick power checks or switch to loaded modes for mapping under steady-state conditions. All main parameters are confirmed by the official manufacturer data and cross-checked against reseller brochures and forum feedback.

Local workshops in Dubai, Abu Dhabi and Sharjah often deal with turbocharged V8 swaps, supercharged six-cylinder projects and even 1000-plus-horsepower drag builds. The 1500brd covers these extremes with headroom to spare. In inertial mode the unit measures up to 650 hp, perfect for baseline pulls on stock engines. Engage the electromagnetic brake and constant-speed mode jumps to 900 hp, letting you hold the car at load sites to fine-tune ignition timing or fuel trims. Finally, the dynamic mode from the wheels is rated at 1250 hp, more than enough for methanol-injected outlaw builds rolling on slicks.

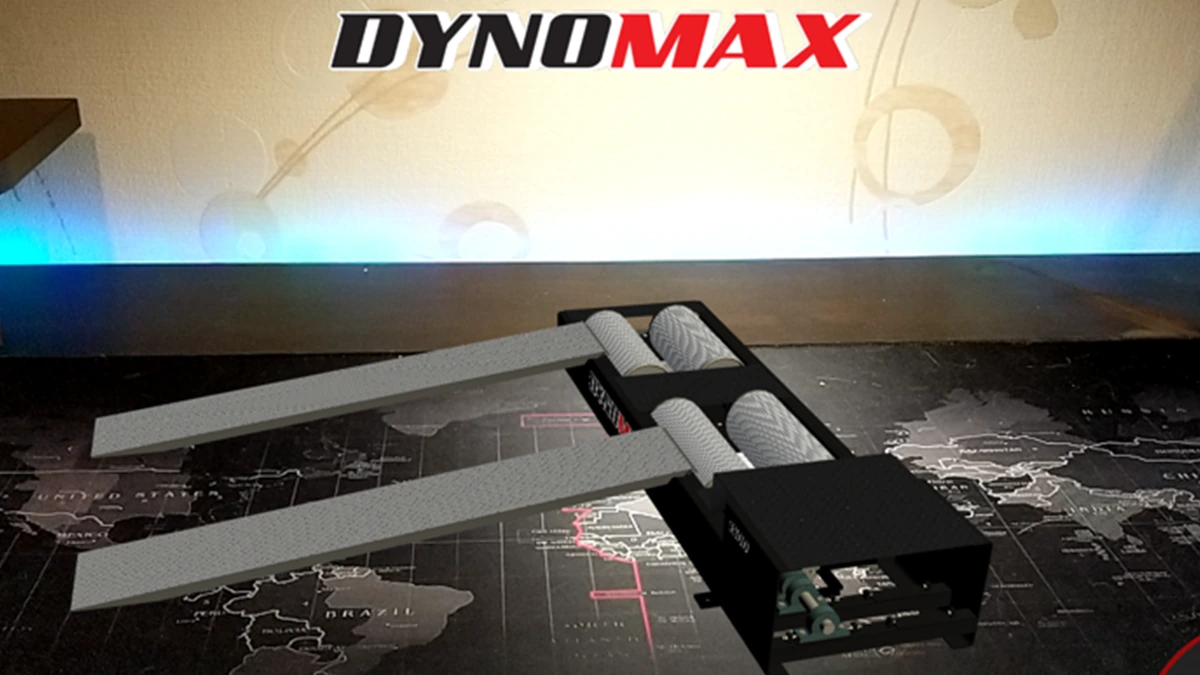

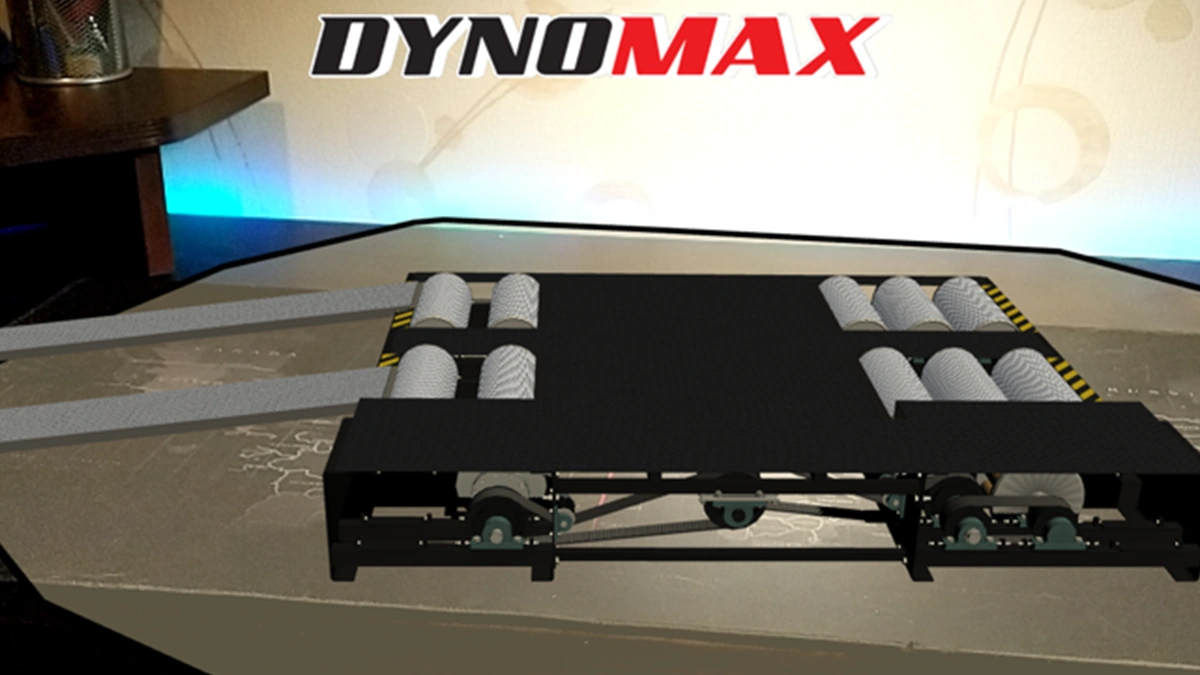

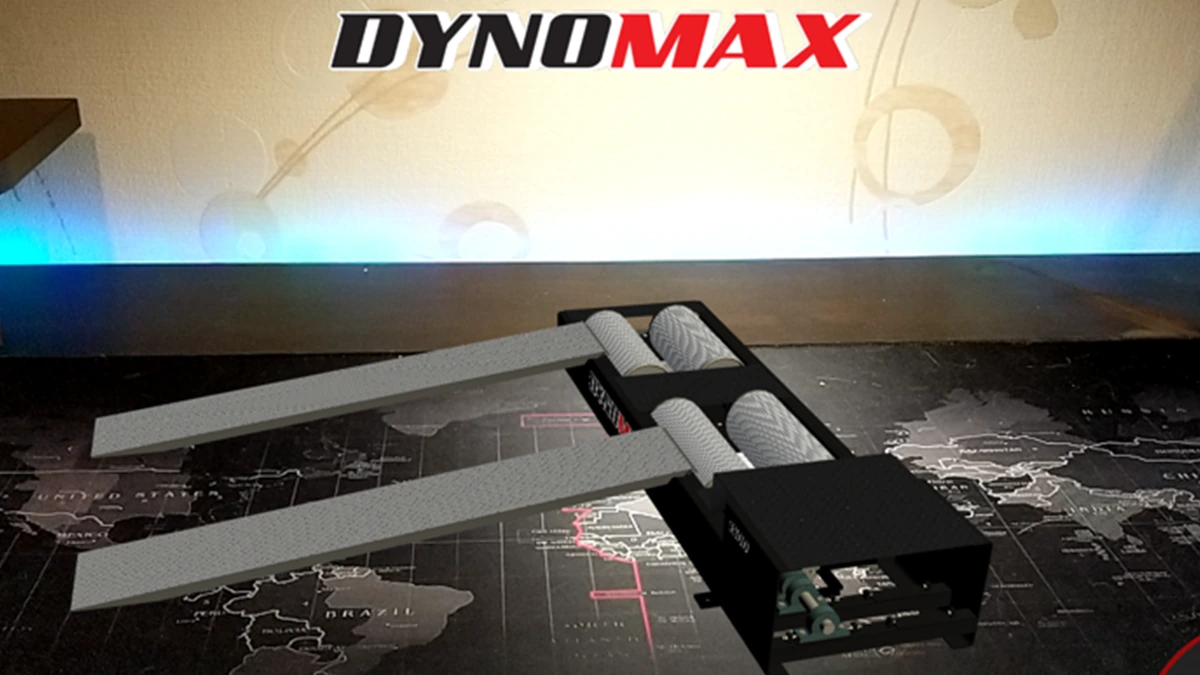

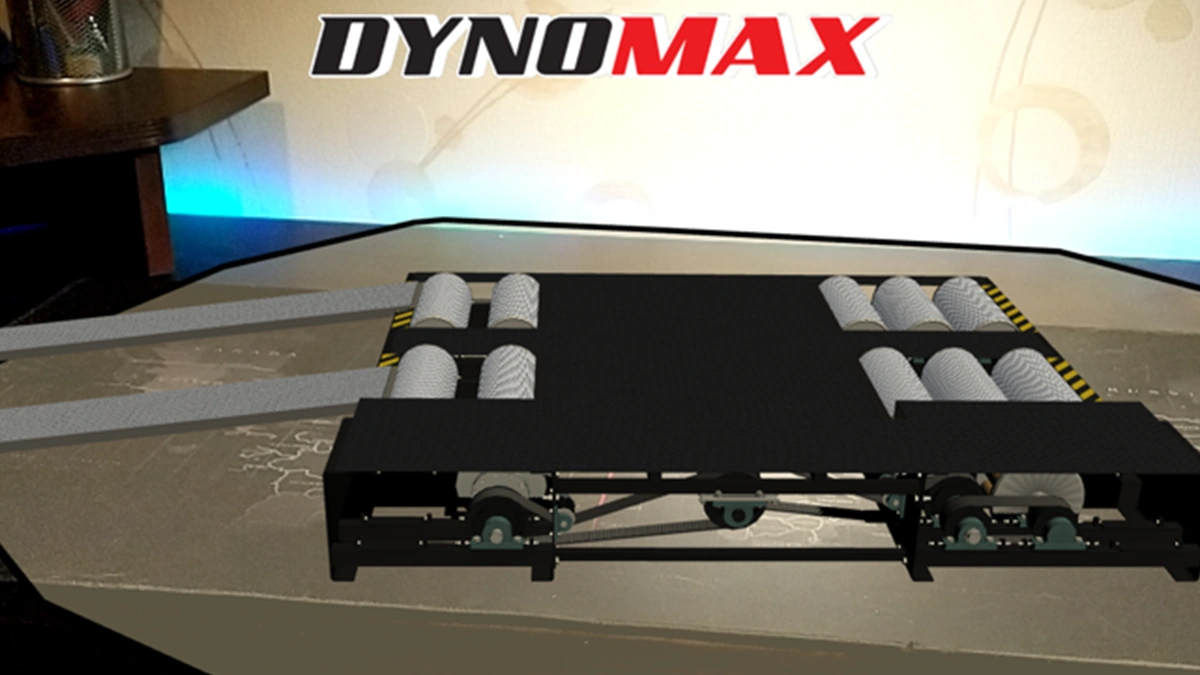

Two drums with 350 mm diameter are linked to extra-wide belts that tolerate sudden torque hits when anti-lag kicks in. The frame uses laser-cut steel boxed sections so it can accept up to 3000 kg per axle. That means you can strap down an S-Class, a lifted Patrol or a track-prepped GT-R without second thoughts.

Before handing over a tuned car to its owner, you need repeatable data. The 1500brd delivers repeatability thanks to 0.1 % accuracy in inertial mode and 1 % in loaded mode. This precision has been verified by independent shop owners on the GCC dyno forums who cross-checked wheel figures against engine dynos and GPS dragy measurements.

A built-in wide-band lambda interface, OBD logging, Wi-Fi weather station and DynomiZer wireless software streamline the workflow. With one laptop you can run ramp tests, overlay runs, add atmospheric correction and email a PDF report before the customer steps out of the waiting area.

Most UAE facilities prefer an in-pit installation so lowered cars roll straight in without scraper boards. Still, the surface-mount kit ships in the same crate, giving you the flexibility to relocate during shop renovations. Standard footprint is 1200 × 3600 mm, compact enough to share a bay with a two-post lift. A minimum wheelbase of 900 mm allows testing of kei cars, while the 2200 mm upper limit covers long-wheelbase sedans.

Switching between modes takes less than 30 seconds. A dashboard toggle in DynomiZer selects:

Your technicians never have to leave the cockpit, so workflow stays safe and efficient.

Competitors like the Maha LPS 3000 and the Mustang MD-500 series dominate many catalogs, yet each has trade-offs. The Maha unit is rated at 280 kph, limiting top-speed aero mapping on high-geared exotics. Mustang’s dual-eddy setup is heavier and needs a dedicated 380 V line that smaller garages might not have. By contrast, the DYNOMAX 1500brd only requires 220 V 16 A service, fits inside the floor recess many shops already poured for older rigs and still hits a verified 300 kph drum speed.

Delivering consistent gains to customers is easier when data capture and safety are baked in. Two infrared roller temperature sensors trigger alarms once surface heat crosses 70 °C, preventing tyre blistering on extended fourth-gear pulls. Over-speed cut-off is set at factory but can be adjusted in 1 kph increments. These small touches keep liability low and throughput high, especially during the busy winter tuning season.

Most Dubai customs clearances are finished within 5–7 working days because the crate weight stays below 2200 kg, so it ships under standard freight terms rather than heavy machinery classification. Once landed, two technicians need roughly 8 hours to anchor the frame, run mains power and connect the pneumatic line rated at 10 bar. Calibration pulls take another 2 hours, after which the bench is ready for its first customer.

The electromagnetic brake uses a sealed rotor with a life expectancy of over 4000 operating hours before pad changes. Replacement pads are stocked in regional warehouses alongside belts and optical speed sensors. Thanks to CAN-bus architecture, any firmware update is a download away, reducing downtime for shops operating six days a week.

DYNOMAX entered the dyno market over 20 years ago and currently offers 14 production models ranging from motorcycle rigs to 4WD monster benches. Approximately 900 units ship worldwide every year, with the 1500brd family accounting for 30 % of sales. The present 2WD BRAKED version is the third revision, integrating customer feedback like wireless EGT modules and a more intuitive UI.