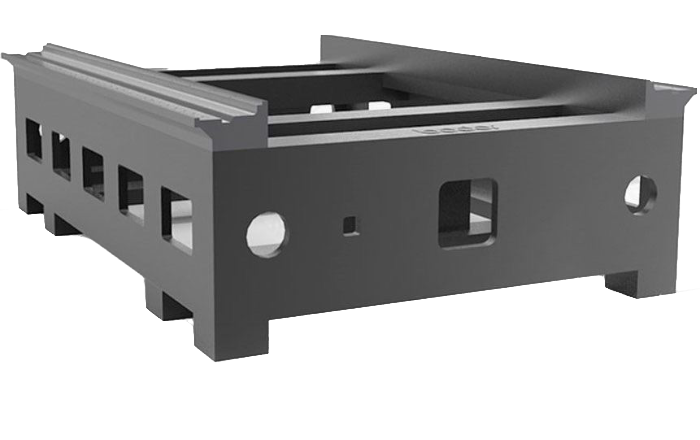

Milling machining center with 3 axes EM800A.

EM800A is a high-precision milling machine from US WHEELER that can be used for machining various materials in metalworking. It features an advanced design and offers high efficiency and precision in operation.

This machine is equipped with an industrial high-precision controller that ensures stable and high-quality processing. The large platform of the machine allows for the machining of parts of various sizes and shapes.

The EM800A has a high-speed spindle that operates at high speeds, providing fast and accurate machining. This machine is also equipped with a cooling system that maintains a stable temperature inside the machine, ensuring high machining accuracy.

The automatic tool change system on the EM800A allows for automatic tool changes, reducing setup time and increasing the efficiency of the machine. Additionally, this machine features a depth control system for milling, allowing for precise control of the machining depth.

Overall, the EM800A is a reliable, high-precision, and efficient milling machine that can be used for machining various materials in metalworking. It boasts a large platform, high-speed spindle, automatic tool change system, and depth control for milling.