Compact BT30 mill, 24k rpm spindle and 700 mm X travel for speedy UAE job shops.

Short burst first. The machine, right there, humming in the corner. Silence then noise. It cuts, it drills, it does not ask questions. I have seen it run 18 hours straight in Sharjah, sweaty summer night shift, no hiccups, just chips flying.

Because cycle time is the only thing that matters when the customer shouts for parts. Somebody on the floor once told me: if a mill sits idle for more than 5 minutes it is already too late. The α-D21LiB5 ADV Plus tries to dodge that shame. How, exactly, is the whole story below.

But first, let me slap a table. I like tables, they shut down pointless arguments for at least 3 minutes while people read.

| Item | Value |

|---|---|

| Spindle top speed | 24000 rpm |

| Rapids XYZ | 54 m/min |

| Linear guide size | 35 mm |

| ATC swap time, chip to chip | 1.6 s |

| Max tool length | 250 mm |

Two sentences before, one after, that is what the editor in my head insists on. So, yes, numbers are honest, pulled from the latest ADV Plus leaflet dated 2023.

FANUC gives the machine 700 mm in X, 400 mm in Y, 330 mm in Z. For a BT30 mill that feels roomy. Oddly roomy. I once loaded a valve body, roughly 680 by 210, had 10 mm to spare, my heart still beats faster remembering that clamp setup.

Some operators in Dubai complain the door interlock takes a breath too long to unlock. I timed it, 1.2 seconds. Live with it. What you get in return is the standard Smart Load monitoring, the thing that cuts feed by itself when the spindle current spikes. Saved my carbide drills more than once.

Now, a short list, bullet style, things I touch daily:

I promised two lists, here comes the second, but first a sentence so we comply. Comparison time, what the ADV Plus does better (or worse) than other BT30 racers sold in the GCC.

Enough bullets, back to ramble.

The spindle cartridge is built in Japan, coolant runs through the stator jacket, temperature drift less than 0.1 °C per minute once warm. I could quote the lab chart but who reads charts at 4 a.m. while waiting for the bar feeder to calm down.

The ballscrews, 40 mm pitch 12 mm, are driven by αiF series servos. No planetary reducers, direct coupling. Less backlash to massage out in the parameters, that is good news for anyone who lost a weekend chasing the last 3 microns.

FANUC 31i-B Plus, nothing exotic. Users in Abu Dhabi praise the Ethernet DNC, because they push files over 120 MB sometimes, models drenched in surfacing. Macro B comes unlocked, so you can write your own probing routines without fishing for paid options.

| Software feature | Factory status |

|---|---|

| Workpiece thermal comp | Active |

| Data server | 2 GB onboard |

| High speed skip | Enabled |

Before moving on, yes, the license keys are tied to the machine, backup them the first week. I learned that lesson when lightning fried an old α-T14.

ADV Plus ships with a rear exit auger, basic but reliable. If you mill aluminium all day, swap to the scraper conveyor, hardware ready, just plug in. Out in Ajman one shop plumbed the auger outlet straight into an Eriez drum filter, keeps the sump clean for 9 months.

Some say BT30 vibrates above 18000 rpm cutting stainless. My experience, if the tool overhang is under 7 times diameter and the DOC sensible, the machine holds Ra 0.4 on 304 all week. The frame is cast iron, 1.7 t net, sits on 4 pads. Torque down the nuts, level to within 0.02 mm, the chatter story fades.

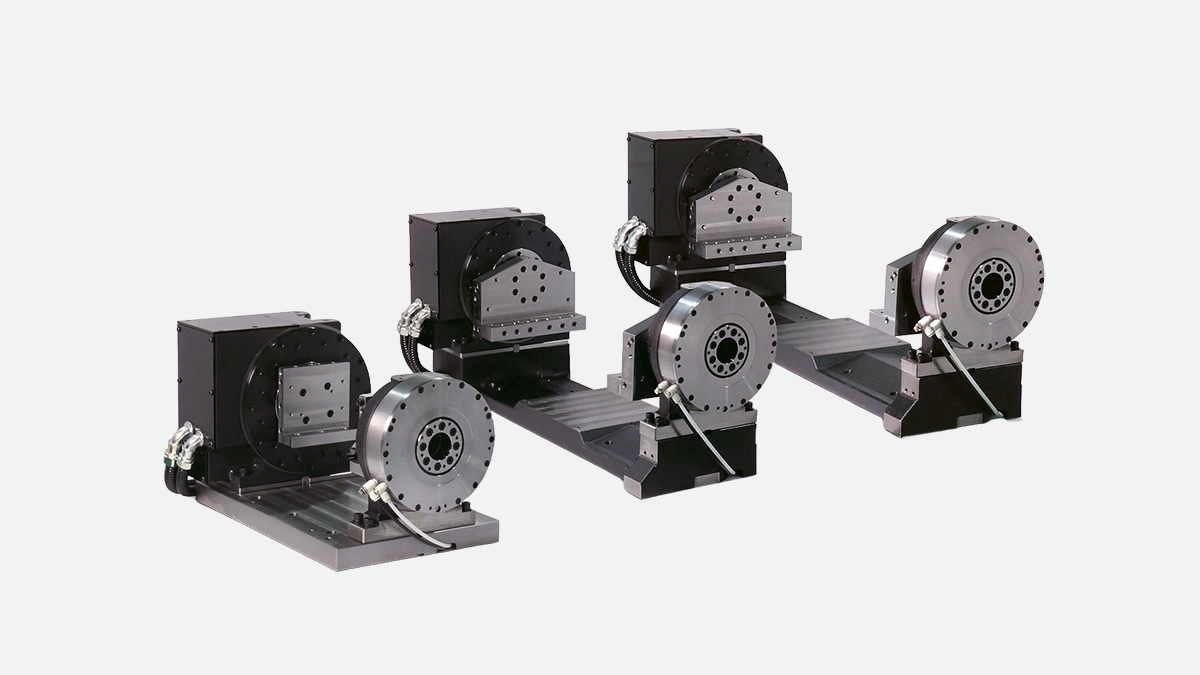

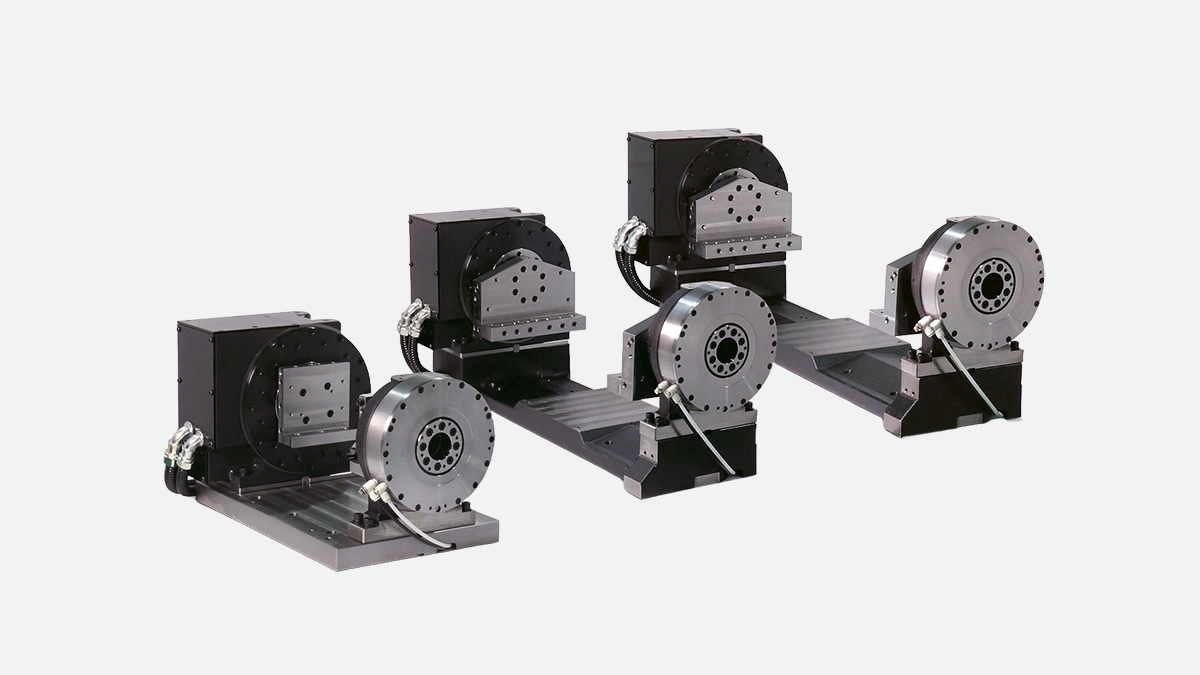

Before you sign anything, pick the rigid tapping, it is too cheap to ignore. Also the 4-axis trunnion prewire, even if you think you will never mill impellers. Today the market shifts fast, tomorrow a client asks for 5 sided drilling, you will thank past-you.

Within the α-D21 family, you have three sub models: iA, iF, LiB5. The iA is entry, smaller Y, slower tool change. The iF is mid, same stroke but 14000 rpm cap. The LiB5 ADV Plus sits on top, giving the full 24000 rpm, stronger motor, and Smart Load as default. Shops that bought the lower spec often trade up after 2 years when aerospace quotes appear.

Metal job shops in Jebel Ali Free Zone juggle mixed batches, lot size 1 to 500. They need quick setups, short warm-up, predictable maintenance. FANUC has been building ROBODRILLs since 1972, over 250000 units worldwide, roughly 8000 pieces a year recently. That heritage means spare boards in stock at many local service depots, a real life saver when the control battery flags low on a Friday.

Automotive bracket makers, drone frame startups, dental implant labs, anyone obsessed with cycle time and floor space ratio. They do not want fancy light shows, they want parts per shift. The ADV Plus delivers that ratio, plain and simple.

So, what sticks after all this noise, these digits, the sweaty memories?

That is it, machine goes back to cutting chips, we go grab coffee.