Vertical machining centers Alpha V11L and V9L.

The machine represents a high-precision tool designed for processing various materials, including metal, plastic, wood, and others. It is equipped with powerful and reliable components that ensure high performance and processing quality.

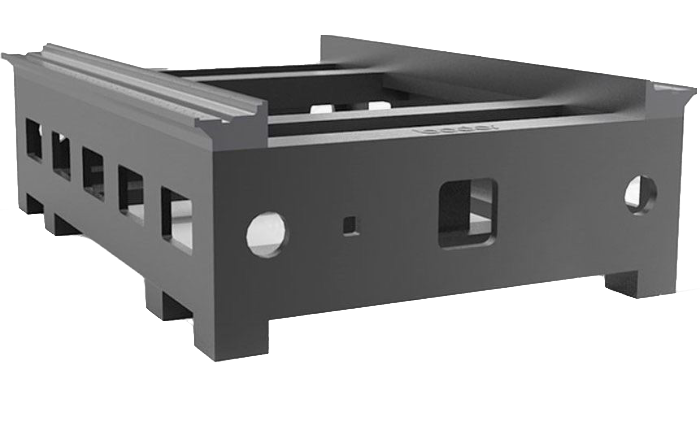

The V11L and V9L models feature a user-friendly design and compact dimensions, making it easy to place them in a workshop or production area. The machine is equipped with a high-speed spindle that provides accuracy and smooth operation.

Key advantages of the V11L model from PRIMINER:

– Wide range of material processing;

– Powerful and reliable motor;

– High precision and processing quality;

– User-friendly design and compact size.

The V11L machine also comes with a modern control system that allows for easy adjustment and monitoring of the machine’s operation. This makes it an ideal choice for production facilities and workshops where high performance and processing quality are required.

Overall, the V11L milling machine from PRIMINER is an excellent solution for processing various materials, ensuring high performance, accuracy, and quality of work.