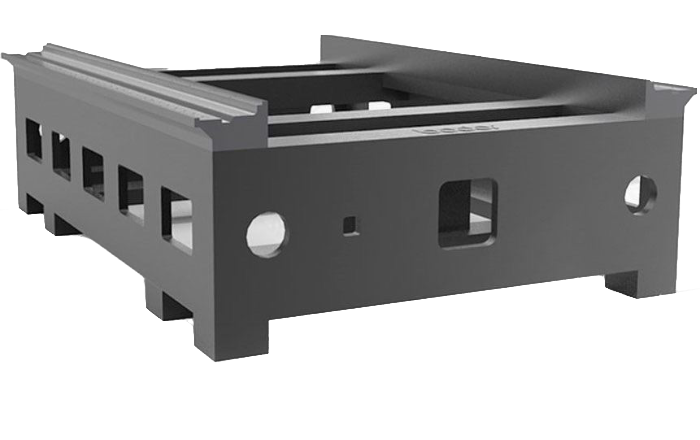

Alpha V13L and V15L machining centers with 3 axes.

The V13L machine from PRIMINER is a high-precision milling machine designed for processing both metal and non-metal materials. The machine is equipped with modern CNC control, allowing for high accuracy and processing speed.

A key feature of the V13L machine is its high performance. It is equipped with a robust spindle that can process materials at high speed and precision. Additionally, the machine has a large working area, enabling the processing of oversized parts.

The V13L machine also boasts high stability and reliability. It is made from high-quality materials, ensuring a long operational lifespan. Furthermore, the machine has a built-in cooling system that prevents overheating and extends the life of the tools.

This machine is versatile and can be used in various industries, including automotive manufacturing, medical equipment, tool production, and many others.

In conclusion, the V13L machine from PRIMINER is a reliable and efficient tool that will speed up the production process and achieve high accuracy and quality in material processing.