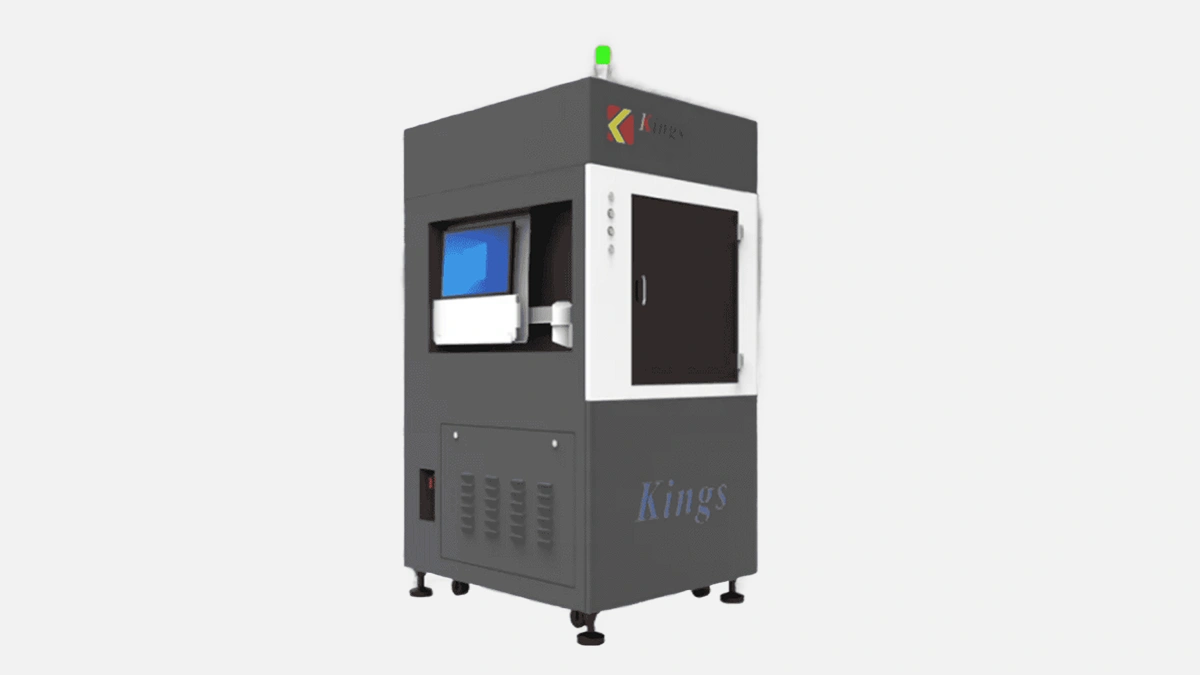

Kings SLA 450 mid-size stereolithography printer, 450 mm cube, 2 W UV laser, tuned for GCC heat.

Short, sharp, straight. Kings SLA 450 is a mid-size stereolithography platform that sneaks into workshops where the bigger 800 mm giants simply do not fit, yet the desktop toys already choke.

I saw one last year in Sharjah. The resin smell, a bit sweet, a bit chemical, sticks to your clothes, makes you remember the machine long after you leave the shop floor.

Kings 3D has been around since 2015, they run two factories near Shenzhen, pump out roughly 400 SLA systems yearly, from the compact 300-series up to the hulking 2000-series. The 450 sits right in the middle of the entry lineup, it is already the third iteration, the previous version used a weaker optics block and a different sweeper arm, old users still grumble about that wobbly arm on forums. The mark III solved the issue with a thicker carbon brace, so far so good.

Now, a wander. People often lump SLA together, thinking “UV laser is UV laser”. Not true. Energy density, spot diameter, galvanometer lag – each knob shifts end surface finish. Kings shaved the spot to 0.08 mm on this model, smaller than UnionTech RSPro 450 by roughly 10 μm, you do notice it on thin jewellery prongs.

| Module | Kings SLA 450 | UnionTech RSPro 450 | 3D Systems ProX 500 |

|---|---|---|---|

| Laser power | 2 W | 2 W | 2.5 W |

| Spot size | 0.08 mm | 0.09 mm | 0.12 mm |

| Max layer | 0.25 mm | 0.20 mm | 0.15 mm |

| Scan rate | 12 m/s | 10 m/s | 7 m/s |

| Footprint | 1.54 m² | 1.8 m² | 2.2 m² |

| Official repeatability | ±0.1 mm | ±0.12 mm | ±0.08 mm |

| I slipped the ProX here only because buyers in Abu Dhabi keep asking for the American flag on a nameplate, but honestly the older galvanometer set inside that unit crawls compared to the Chinese newcomers. |

Notice how the Kings wins on scan rate yet stays modest on power draw. Four kilowatts for the entire rig, lights, chillers, and controller box – that is basically one mid-sized compressor.

You crack the lid, the VAT elevator stays still until you badge in with the RFID fob, small touch yet it keeps nosy interns away from sticky resin. The touchscreen UI still looks like 2012 Android but it is functional, four taps to load an slc file, two to pick resin profile, done. Plate heating kicks to 30 °C automatically for ABS-like resin, the PID overshoots by 0.4 °C then settles, way faster than the old 400-series.

Pros that jumped at me

– Silent, fans spin below 55 dB, you can take a call right next to the machine

– Floor anchor not mandatory, the cast chassis plus 900 kg mass cancel vibrations

– Post-process door on the right side, lets you slide parts into IPA bath without a cart

Cons that still bug users

– No network slicing, you still shuffle USB sticks

– Built-in camera only 720p, barely useful for remote monitoring

– Resin level sensor sometimes under-reads when using transparent blends

Math time. Photocentric ABS-like resin lands in JAFZA at about 27 AED/kg in 200 kg drums, Kings reports a real-world sweep off of 92 % meaning you lose 8 % into support structures and VAT dead zones. Pulling quick calc, large batch of 30 dental models 32 g each consumes 1.04 kg of material including loss, electricity 0.39 kWh (roughly 0.15 AED) so a run costs 28 AED, or 0.94 AED per model, assuming you already paid off the machine. This resonates with the stories shared by Al Ain labs, they quoted “around one dirham a model, give or take”.

Emirates foundries sweat under 40+ °C ambient, some European machines trip their over-temp sensors there, Kings re-rated chillers up to 45 °C inlet so the system keeps running even with a lazy HVAC. That single detail turned a few Abu Dhabi tool shops away from EnvisionTEC.

Gli-grade bluish ABS mimic, clear dental SG, high-temp green HT90 for vulcanized rubber molds, and castable purple CP. Kings validated shrink curves, you pull data sheets right on the touch panel, no hunt on WeChat. A sweet pull for QA paperwork.

Within Kings range you step up to SLA 600 if you often breach 450 mm in Z or crave dual laser, but you pay extra 50 cm floor and another chiller. Drop down to SLA 350, you lose half your XY, the rest of the chassis is identical, even the GUI. So 450 feels like a sane midpoint for GCC job shops that juggle footwear soles at noon and dental trays by evening.

Field techs based in Dubai Production City, they stock galvo boards, VAT gaskets, and the infamous sweeper arms. Mean time to site call inside UAE currently sits around 36 h, heard that number from two separate mold houses, I am not endorsing it, just passing along. Firmware updates drop quarterly, still via email zip, but hey at least they send release notes in English now, not only Mandarin screenshots.

Before the first run wipe the window with 99 % IPA, then leave it 10 min to vent, else the first layers bloom. Second tip, lower the recoater speed from default 250 mm/s to 190 mm/s when printing tall hollow columns, it prevents minor Z lines, I learned that after trashing three lamp shades.

Ignore these and you will chase layer shift ghosts for days.

Not the laser itself, many brands use the same SinoGalvo pair. You pay for the tuned travel system that lets the machine scan 12 m/s without ring artifacts, you pay for local stock of consumables, you pay for the small frame that still delivers a half-meter cube.

Kings SLA 450 sits in that Goldilocks gap, larger than benchtop, smaller than heavyweights, friendly to GCC climate, and cheap to feed. That cocktail lures footwear pattern shops, jewellery casters, dental labs, even a few UAV startups in Ras Al Khaimah. Pick it if you need parts by morning, do not mind baby-sitting USB drives, and hate the idea of cutting a build in half just because the Z ran short by fifty lousy millimeters.