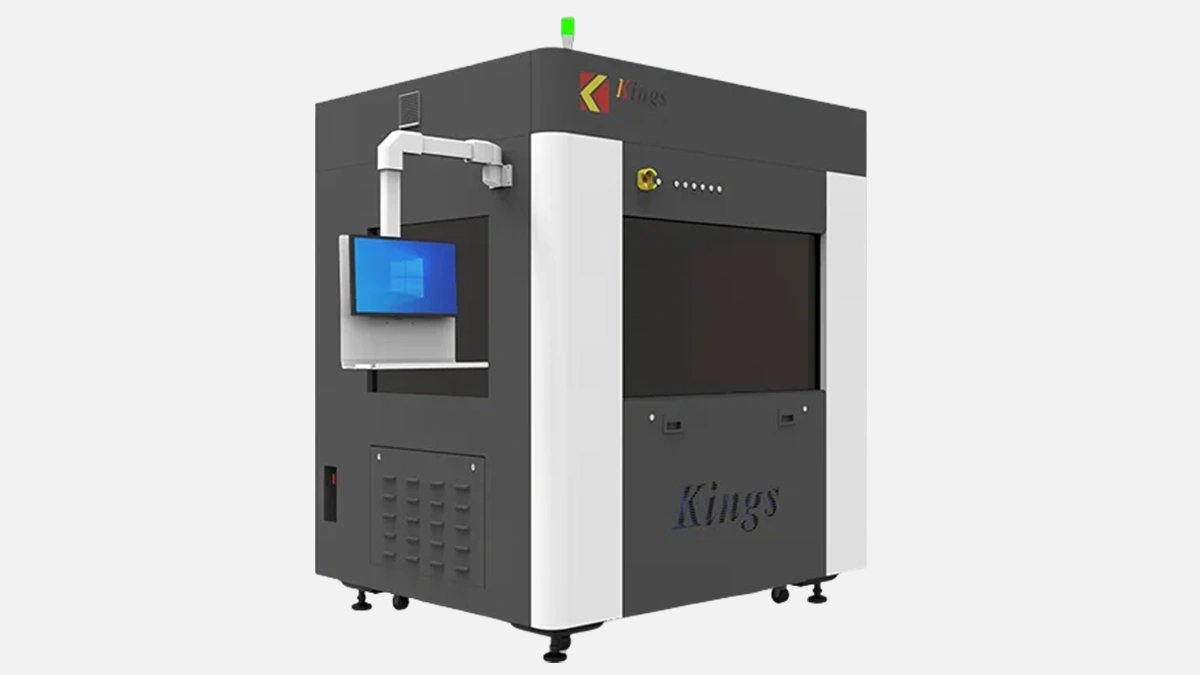

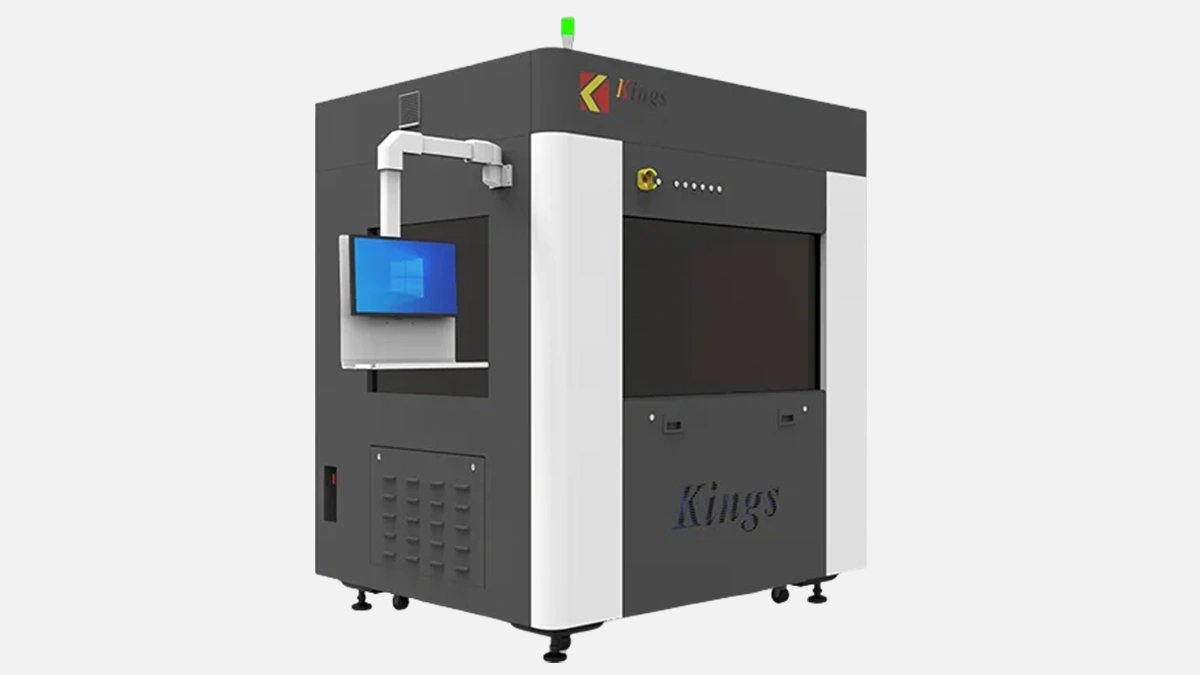

Kings SLA800: 800×800×450 mm SLA printer for fast master patterns and moulds.

Kings. Ten years on the market, three iterations of the same body, more than 500 units shipped worldwide, and here we stare at the chunky SLA800.

Short phrase: big vat, steady beam, long shifts. That is the elevator pitch. The longer story jumps back to 2018 when Kings 3D rolled out the first SLA800 to replace a pair of their older SLA600 units that were constantly overbooked by shoe-last makers in Dongguan. Version one had a smaller door, annoying hinge, limited firmware, whatever. Fast-forward to 2023, firmware 3.x, upgraded motion cards from Beijing Leetro, new chiller loop, here we go.

Oil and gas fixtures? Sometimes. Footwear moulds? More often than you think, Sharjah has a cluster. Foundry patterns for investment casting? That is the juicy part, especially once you do sand casting of aluminium valves and need net-shape masters the next morning. Traditional CNC can carve the pattern from PU board, true, yet you burn half a week, you clean chips everywhere, and your operator drinks three extra coffees. The SLA800 drops a 450 mm tall master overnight, hands free, and the surface already sits around Ra 0.8 µm after a quick IPA bath. No dust, no metal chips, only the sweet smell of uncured resin.

Before diving further I will pin a small table, numbers speak louder:

| Item | Value | Why it matters in the Gulf |

|---|---|---|

| Build volume | 800×800×450 mm | Fits pump casings and shoe-last boards in one go |

| Laser power | 450 mW | Cuts through viscous resins even at 28 °C shop floor |

| Layer range | 0.05-0.25 mm | Toggle between showpiece gloss and rough draft speed |

| Scan speed | 10 m s⁻¹ | Keeps cycle time under 12 h for a full tray of valve cores |

| Electric load | 7 kW | Lands safely on a standard 32 A circuit in Dubai |

Numbers aside, a single detail often ignored: the Z-ball-screw uses a 40 mm diameter shaft, ground class C5, so backlash basically hides under 5 µm even after one year of sand-blasting heat.

The viscosity sensor hooked into the resin tray sends a ping every 2 min, the firmware decides whether to stir the paddle. Sounds minor, saves a batch of ceramic-filled resin when the AC fails at noon.

You power up, the GUI does a 90 s self-diagnostic, checks laser temp, chiller loop, galvanometer drift. Swipe right, load the sliced file via LAN or the ancient USB slot, stop snickering, some shops still insist on sneakernet. Once the job starts you are free for the rest of the shift, the only human touch needed is to peel the cured cake from the vat edge after print layer 200 so it does not weld itself. Takes you literally 15 s with a plastic spatula.

After print, move the tray to the UV oven, which is just a repurposed stainless drum with 36 LEDs inside, sell the old metal-halide lamp already.

Some Gulf users skip full sanding and go straight to silicon molding, they only run a quick 240-grit hand wipe plus a thin coat of autoclear. Saves half a day. That strategy works because the SLA800 beam footprint is under 0.15 mm, edges come out crisp, draft angles stay intact.

Most machine shops in Abu Dhabi landed on the SLA800 after doing the math, build area versus floor rent is better.

Let us be blunt, the main rivals are UnionTech RSPro 800 and 3D-Systems ProX 800. Quick rundown:

The price gap? I promised not to talk numbers here, just note that Kings historically positions itself around 30 % below the US brand while throwing a two-year laser warranty into the box.

Another bullet list because this part is usually buried in footnotes, and then people act surprised when the galvanometer fries:

Two sentences to wrap this up: there is no messy recoater blade here, Kings uses a dip-and-retilt mechanism, fewer moving bits. The only consumable beyond resin is the Teflon release film, 0.2 mm thick, slide it out, slide new sheet in, done.

Footwear moulders, dental labs that run BIG implant guides, art studios printing mosque miniature domes, even a drone housing start-up near JAFZA. The common thread, they all need surface finish straight out of the vat. They also value that the chassis fits in a freight elevator.

In short, SLA800 does not try to be everything, it just keeps churning parts while the AC hums above 24 °C. That is it, no fluff.

The machine lands in a wooden crate, you wire it to a three-phase 380 V feed, fill the vat, press start, sleep. Less headcount per shift, tighter tolerances on master patterns, predictable cycle time. Those three points drive purchasing teams in Dubai and Sharjah to sign the PO.

Kings backs the unit with regional service via a small tech cell in Ras Al Khaimah, response under 48 h, parts shelf filled in advance. That simple assurance tilts the decision for many mid-size job shops.

So, if you need a resin workhorse that fits the corridor, drinks 7 kW, and does not whine about Gulf humidity, the SLA800 sits high on the candidate list, full stop.