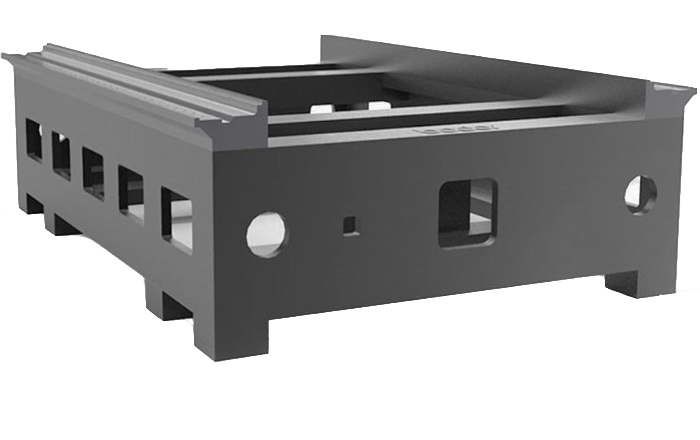

High-performance machining centers of the VF series. Models: VF900, 1100, 1300, 1500.

VF1100 is a high-precision vertical machining center developed by the Chinese manufacturer PRIMINER. It is designed for the production of complex parts, such as mechanical components and tools, as well as for other industrial applications. The VF1100 machine is characterized by high machining accuracy, high productivity, and long service life.

One of the main features of the VF1100 machine is its design. It provides stability and machining accuracy even at high spindle speeds. Additionally, the machine is equipped with a high-precision control system that ensures accuracy and reliability in operation.

The VF1100 has high productivity and can operate at high spindle speeds. It is equipped with a powerful motor that allows for high-speed and high-precision machining. As a result, the machine enables the processing of complex parts in the shortest possible time.

Furthermore, the VF1100 has a long service life due to the use of high-quality materials and modern manufacturing technologies. It boasts high reliability and durability, allowing for high-quality machining over many years.

In summary, the VF1100 is an excellent solution for companies seeking a high-precision and high-performance machine for machining complex parts. It offers numerous advantages, including high accuracy, high productivity, and a long service life. If you are looking for a quality vertical milling machine, the VF1100 is an excellent choice.