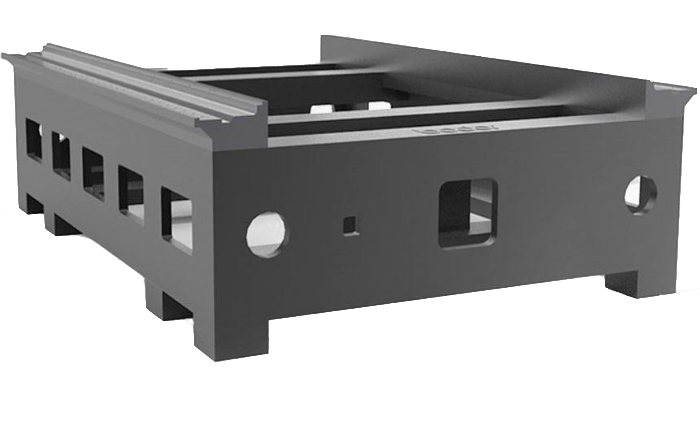

CNC Turning Machining Center LT210 from US WHEELER.

The US WHEELER LT210 turning machining center is a high-precision machine designed for processing metal and non-metal parts. It is characterized by high performance and processing accuracy, allowing for the production of quality blanks and components.

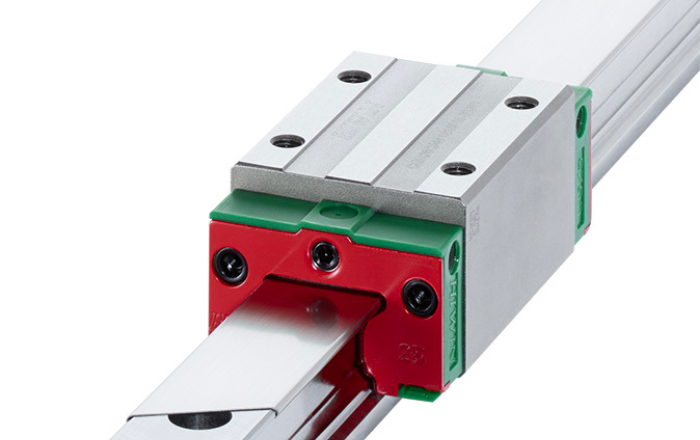

The main technical specifications of the LT210 machine include a powerful spindle capable of operating at high speeds, as well as a large work table surface. This enables the machine to process larger-sized parts, making it an ideal choice for the production of large blanks.

The LT210 is equipped with a high-precision control system that achieves maximum accuracy and speed in part processing. This system ensures the stability and reliability of the machine’s operation, while also allowing the operator to manage it easily.

Additionally, the LT210 features a modern design and compact dimensions, making it convenient to use in small shops and workshops. It is also known for its high reliability and durability, making it an excellent choice for manufacturing enterprises across various industries.

Overall, the US WHEELER LT210 lathe is a high-tech machine that stands out for its quality, precision, and productivity. It enables the quick and efficient processing of parts of various complexities and shapes, making it indispensable for the production of large blanks and components.