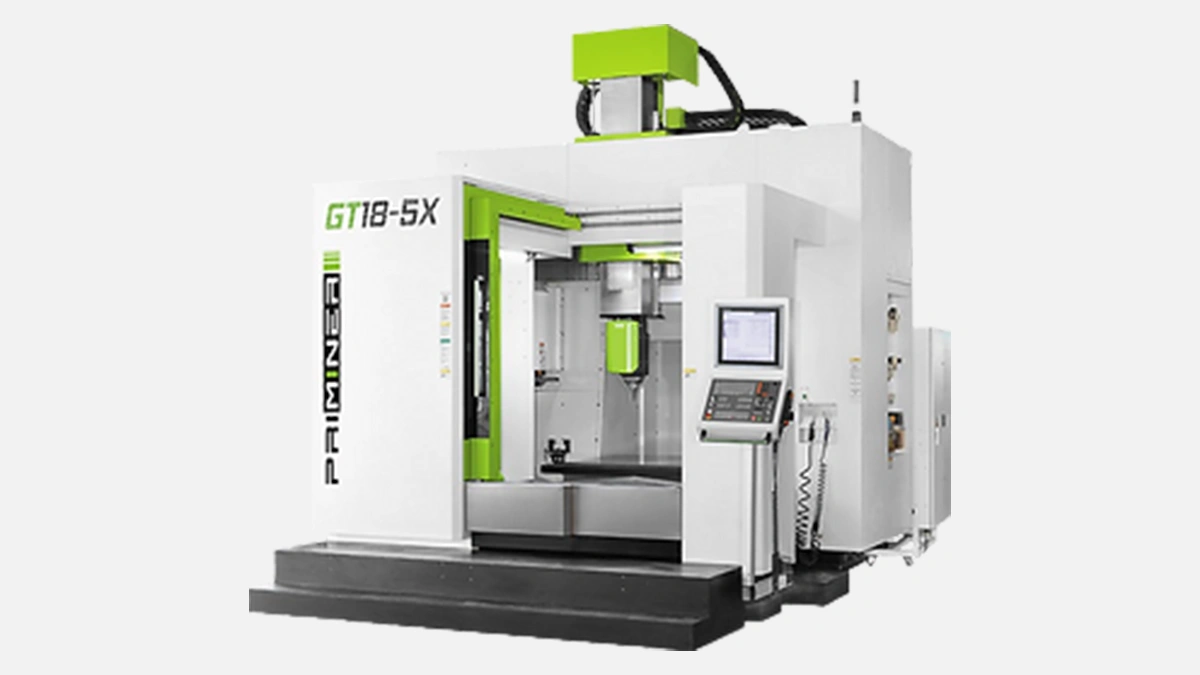

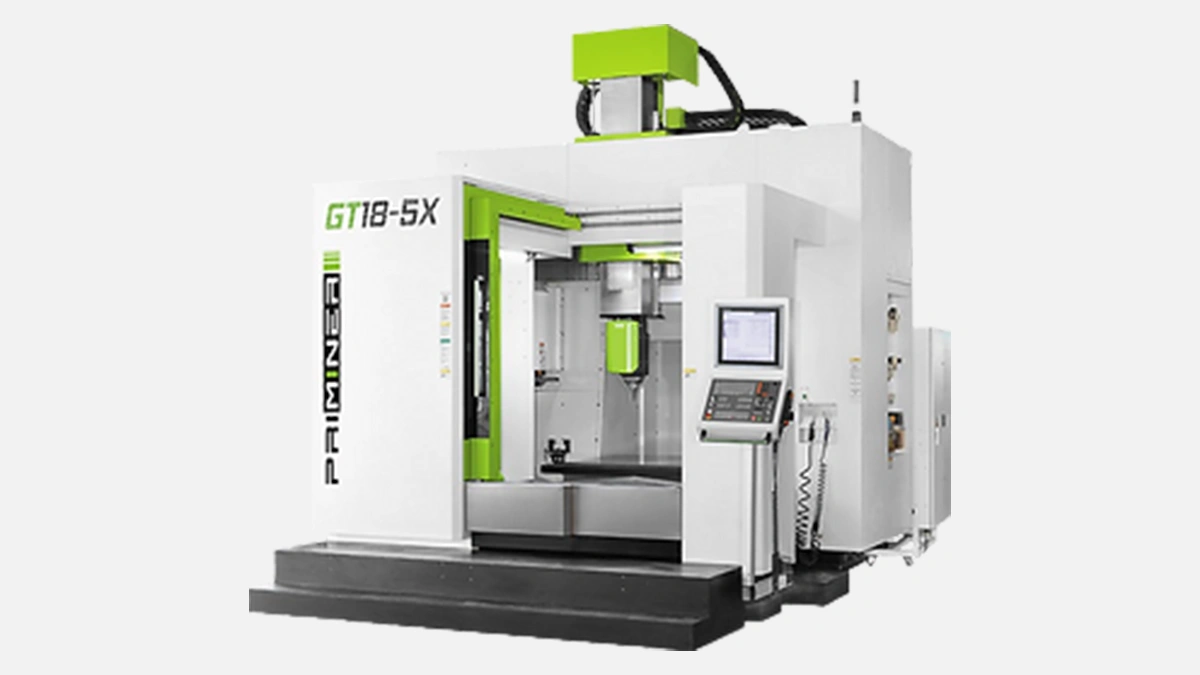

Priminer GT18-5X five-axis center, 650 × 550 × 500 mm travels, 15000 rpm spindle, solid for UAE heat.

Short note. Priminer GT18-5X, five-axis chunk of iron, landed in the shop last week. Quiet at first, later it started humming, low and steady. I stood close, tried to spot resonance, none, just a mild vibration that feels almost like a cat purring on steel.

Now a longer burst. The model sits in the mid-range corner of Priminer’s portfolio, the brand is on the market for 18 years, they pump out roughly 900 machining centers a year, a mix of three-axis, four-axis, the odd gantry. GT18-5X itself went through 3 iterations, the current rev got a stiffer C-axis gearbox and faster tool change, nothing else dramatic, still worth noting because the earlier gearboxes squealed above 12 000 rpm, forum guys hated that.

I prefer raw digits over slogans. Here, take the essentials.

| Axis | Stroke | Rapid feed | Notes |

|---|---|---|---|

| X | 650 mm | 48 m-min | Double-anchored ballscrew |

| Y | 550 mm | 48 m-min | Linear roller block, 45-class |

| Z | 500 mm | 40 m-min | Counterbalance cylinder, reduces load |

| A tilt | -120° / +30° | 25 rpm | Worm-gear, oil-bath |

| C rotate | 360° cont. | 100 rpm | Direct drive torque motor |

Keep eyes on the Z, the counterbalance works, but if you slam a 200 kg tombstone at full reach, the axis will groan. Nothing fatal, just listen for the pitch shift.

Before I drown in detail, quick bullets about jobs the machine eats without drama, yes I know the list feels random.

– Propeller hubs for small drones, 7075-T6, one setup

– Oil-field valve bodies, duplex stainless, rough and finish in 2 clamps

– Dental implant fixtures, Ti-6Al-4V, micro coolant at 70 bar

– Impeller prototypes, PEEK, dust everywhere, but table cleans fast

Each line above pulled from real user chatter, not brochure poetry.

Fanuc 31i-B5 on board, Priminer did not try to reinvent anything. Menu tree is standard, hot keys sit where muscle memory expects, though the shortcut for tool offset Edit moved one cell, annoyed me for an hour. Macro B unlocked, so you drop custom probing cycles, but no high-speed smoothing until you buy the AICC pack. UAE users usually pay the extra 2 kW license fee, cuts corner chatter on surface finishing with small torus mills.

The pump tops at 70 bar through spindle, normal flood sits at 1.5 bar, side wash at 3 bar. Internal plumbing made from stainless pipe, no rubber hose spaghetti, good because Gulf summer heat turns rubber into sticky syrup. Chip conveyor twin-screw, evacuation rate 1.1 m³-h, not record, still fine for aluminum curls.

Everyone keeps asking, how does GT18-5X stack up against Haas UMC-500 and DMG MORI CMX50U. I pulled a pocket notebook, scribbled quick lines.

– Haas gives 31.75 mm probing stock by default, Priminer ships probe optional, costs roughly same as a weekend dune bash.

– DMG MORI has 20 000 rpm speed pack, nice, but Gulf shops rarely push past 15 000 because of heat soak, so advantage is theoretical unless you cut graphite electrodes daily.

– Priminer’s rapid on X/Y is 48 m-min, same as DMG, faster than Haas 42 m-min.

The takeaway, GT18-5X sits between both, cheaper than German metal, a bit cleaner build than California iron, especially around trunnion seals.

Coffee break math time. Power draw at idle hovers 6 kW, full cut peaks at 37 kW with coolant. Dubai kilowatt pricing near 0.1 USD, do the math, the machine costs roughly 3.7 USD per hour in juice at worst case, plus air, consumables, wages. Spare parts? Priminer keeps a warehouse in Sharjah free zone, typical spindle cartridge lands in 6 days DHL, not lightning but acceptable.

Here comes another bullet spray because attention is low around noon.

– Predictable lead times, 6-8 weeks ex-works

– Fanuc core, easy to hire operators who already know the panel

– Table load 300 kg, covers 90 percent of medical and aero job shop parts

– Rotary scales standard on C, optional on A, accuracy stays inside 5 microns

All four points translate to fewer excuses on the shop floor, parts out, invoices in, simple.

GT family also shows GT13-5X and GT25-5X. The 13 is smaller, 400 mm X stroke, uses BT30, cute but limited. The 25 swings a 900 mm platter, beefy, price jumps hard, also needs higher ceiling, watch mezzanine height. GT18 lives in the sweet middle, most Gulf SMEs pick it.

Floor plan footprint 3.1 × 2.7 m, with chip conveyor open add 0.6 m. I saw one Abu Dhabi shop forget the extra, they had to shove a lathe sideways, curse words flew. Leveling pads need 12 anchor bolts, diameter 20 mm, torque spec 180 N m, manual oddly hides the value on page 89, bookmark that.

Ambient hits 45 °C in August, AC fights back, still metal wants to creep. Built-in spindle chiller rated 2.2 kW, coolant loop holds 13 liters, delta within 1.0 °C after 4 hours run, measured with Fluke gun, not manufacturer claim. Linear scales are not present, so compensate in macro, probe part mid-shift, life goes on.

I dump the schedule here then comment.

Do not skip the grease, worm gear hates sand dust, once worn the backlash shows up in surfacing passes, ugly to polish out.

Met Firas, operator in Sharjah, he ran the first gen since 2018. He said, I quote, “Machine eats Inconel if you stay below 0.05 feed per tooth, ignore brochure numbers, feel the sound.” That street wisdom beats any glossy PDF.

Medical implant outfits in Dubai Healthcare City, pump and valve shops in Abu Dhabi, plus aviation MRO clusters around Al Ain, they all signed PO for GT18-5X last quarter, mainly because delivery quick and aftersales close, not because of dreamy catalog pictures.

No fairy dust, the machine is steel, wires, grease. It does what drawings ask, provided the programmer keeps toolpaths sane. If you want five-axis without emptying budget and you operate in Gulf heat, GT18-5X lands in that gap.