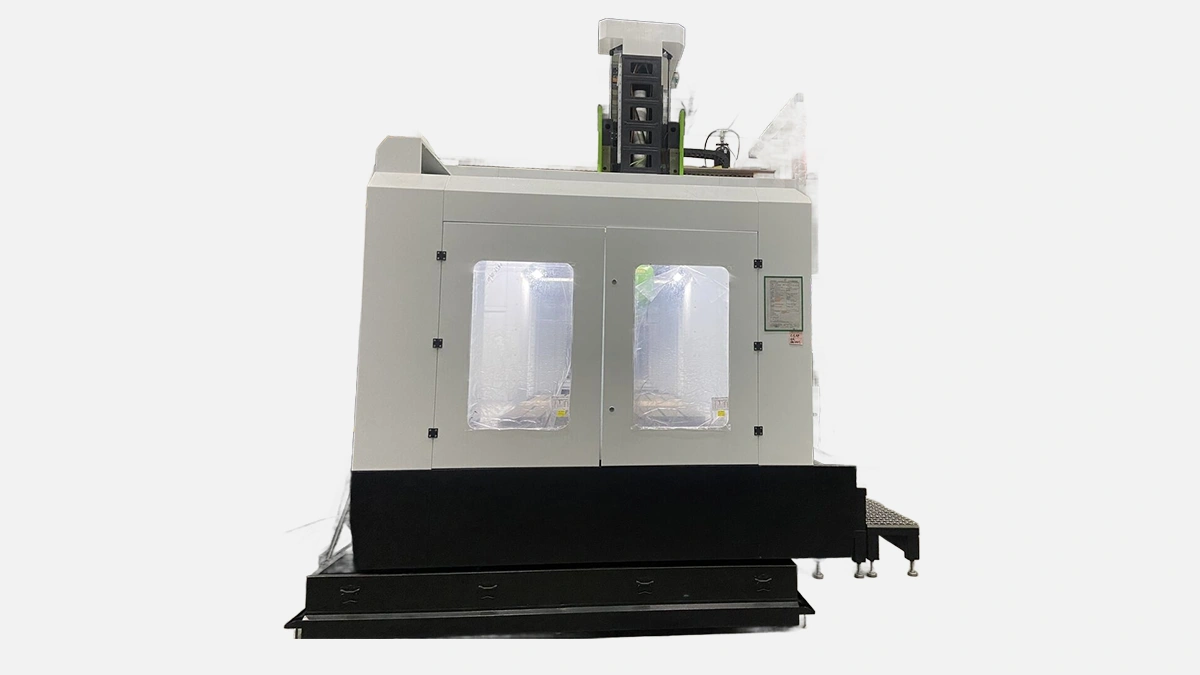

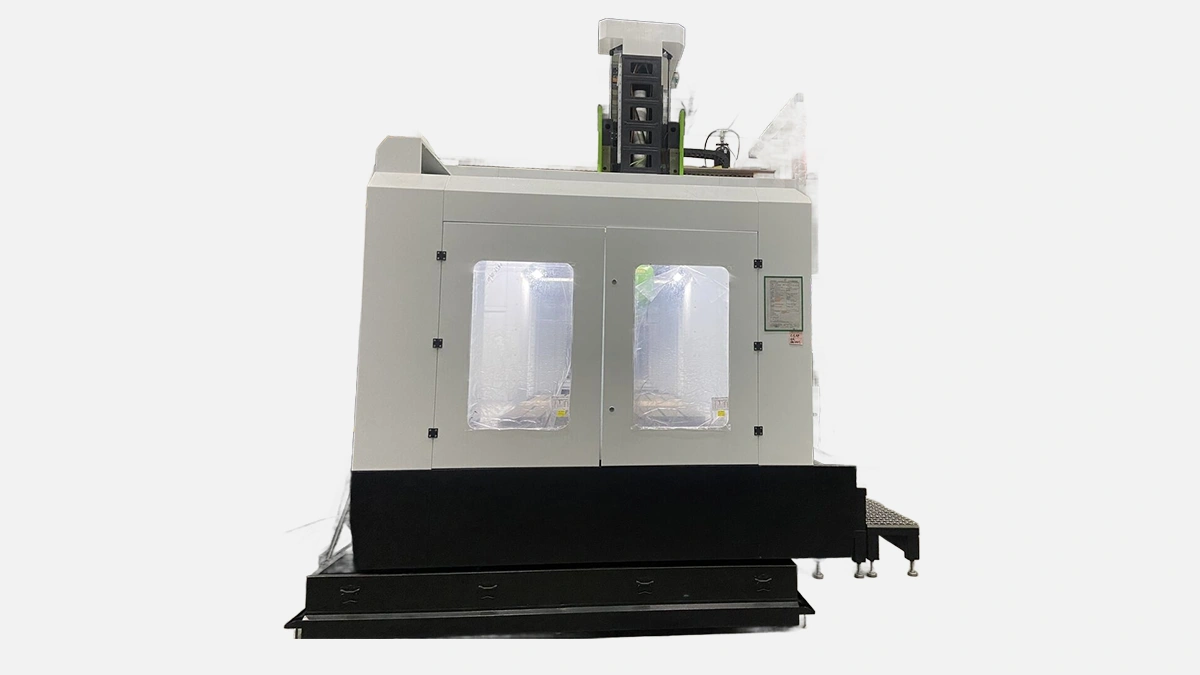

Compact 5-axis center with 320 mm trunnion, 12 000 rpm spindle, built for tight UAE shop floors.

Short morning, noisy compressor in the corner. You flip the breaker, coolant pump coughs, everything wakes up. The GT320-5X stands still for a second, like it needs its own coffee, then the PLC kicks in and the screen glows green. Quiet hum. Nothing dramatic, just metal ready to move.

Dubai and Sharjah job shops went from three axis to five axis almost overnight. Aerospace offset work, dental implants, die and mold for plastic chairs that never look the same twice. Space is expensive, electricity even more, nobody wants a giant horizontal hogging the floor. A 320 mm table feels about right. Big enough for turbine blisk prototypes, small enough to roll through a regular shutter door.

You want numbers. Fair. The table below is dry, no hype, only the digits that decide whether the part ships tonight or tomorrow.

| Axis | Travel (mm) | Rapid (m/min) |

|---|---|---|

| X | 600 | 40 |

| Y | 450 | 40 |

| Z | 400 | 40 |

Those rapids are not record smashing yet they keep the ball screws calm, servo heat stays predictable, the glass scales do not drift even when the AC in the shop fails for half a shift.

Before any aluminum chip lands on the splash guard you care about the heart, right, the spindle. Priminer bolts in a 15 kW cartridge rated for continuous duty at 12000 rpm. Torque curve is pretty flat up to about 4000 rpm, then it climbs, holds steady till 9000, nice for titanium lugs. Bearings are ceramic hybrid, grease pack, no external oil chiller, so less hoses to leak. Drawbar force sits around 15 kN.

The trunnion? Cast iron base, twin rotary axes driven by Harmonic gearboxes, both clamp hydraulically. A axis swings +110° /- 30°, C axis goes full 360° nonstop. Repeatability on the tilt sits inside ±3 arc-sec if you baby the encoders.

Two sentences then a list. Here we go. The machine behaves polite, no sudden banging, even when finishing Inconel.

Cool, but nothing is perfect.

I promised honesty, so quick bullets again after one sentence of intro. If any line below hurts, at least you knew before the invoice.

Priminer ships the unit with FANUC 0i-MF Plus. Old friends in Abu Dhabi get around it blindfolded. Look ahead buffer is 2000 blocks standard, hardware high-speed curves sit inside. Ethernet handshake is plain, DNC drip feed at 6000 blocks per second tested by a crowd on Practical Machinist, nobody complained.

Some shops ask for Heidenhain TNC 640 and yes, Priminer will fit it, but lead time stretches by roughly 8 weeks.

Short, choppy, straight.

| Model | Table Ø | Spindle (rpm) | Power (kW) | Footprint (m) |

|---|---|---|---|---|

| Priminer GT320-5X | 320 | 12000 | 15 | 2.3 × 2.6 |

| Haas UMC-500 | 500 | 15000 | 22 | 2.8 × 3.4 |

| DMG MORI DMU 50 | 650 | 20000 | 20 | 3.2 × 4.0 |

| Kitamura Mytrunnion 4G | 400 | 12000 | 15 | 2.5 × 2.9 |

Priminer sits narrow. Power is modest yet steady. If your shop squeezes every square meter, the GT320-5X gives 30-40 percent smaller footprint than the two European units above.

GT320-5X has two bigger cousins, GT420-5X and GT520-5X. Same cast base, longer travels, upside is more swing room, downside is price tag and air freight weight. Many Emirati mold makers grab the 320 first, validate their five axis workflows, then upgrade once the order book justifies the leap.

A tooling shop running 17 of these since 2020 shared that average spindle uptime hits 83 percent measured over six months. They run mostly P20 molds, low volume hot runner inserts. Key failure so far, one trunnion rotary seal tore after 11,000 hours, replacement took one afternoon. That is it.

Priminer counts 18 years on the market, roughly 4000 machining centers shipped, seven full variants of the GT series, three iterations of the 5X head. Spare parts warehoused in Jebel Ali free zone, FedEx next business day across UAE. Not the biggest fleet, yet enough to find used boards if the warranty expired.

Long sentence incoming hold tight. If you chase cycle time on 7075 impellers, use trochoidal roughing at 12000 rpm and 12 mm radial step, keep axial step 1.2 × tool diameter, then finish with barrel tool 50 mm radius, leave 0.08 mm stock per wall, the surface blends come out below Ra 0.4 µm without polishing.

Having said that, small heat sinks for LED housings machine best at 8000 rpm, HSK-A63 arbor, HPC coolant 70 bar. The spindle nose takes it, no leak past labyrinth. Love that.

One table, then I shut up. Bold numbers, like you asked.

| Item | Year 1 | Year 2 | Year 3 |

|---|---|---|---|

| Preventive service | 0.9 percent of capex | 1.1 percent | 1.3 percent |

| Consumables | 2.2 percent | 2.4 percent | 2.6 percent |

| Downtime hours | 28 | 35 | 31 |

Even with creeping costs, the machine keeps ROI inside 24 months for mid-size subcontractors doing medical fixtures in Ras Al Khaimah.

Enough figures. Gut feeling matters too. The GT320-5X does not scream premium, it just works, holds micron class on aluminum, holds 7 microns on Inconel when cared for. For plants juggling daily changeovers, that balance between compact frame and full five axis interpolation saves stress. And stress reduction sells machines, more than any buzzword.

Choose it when you want five axis muscle without killing floor space or payroll on exotic controls. That is why fabricators from Dubai Investment Park to Fujairah port keep placing orders.