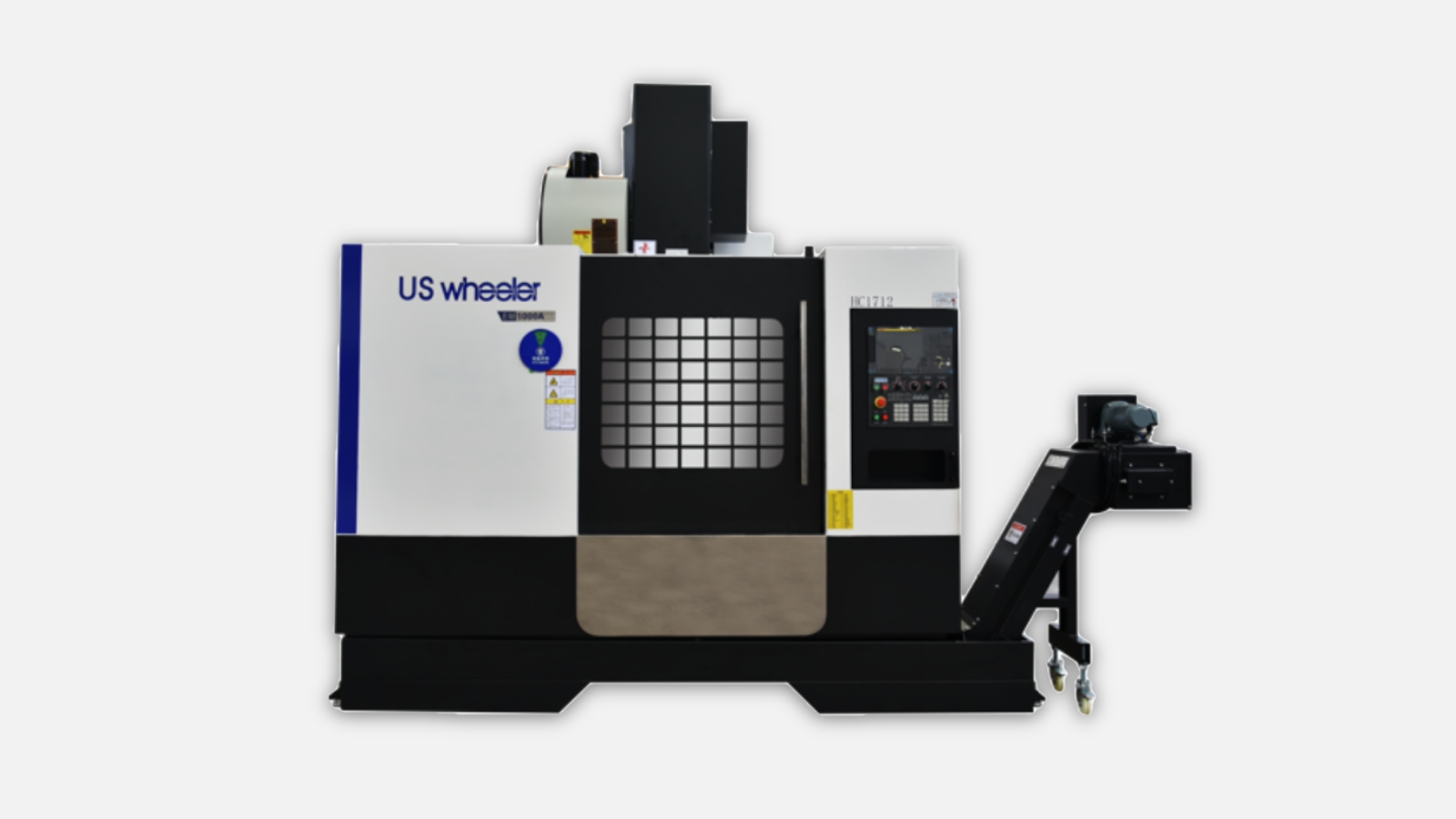

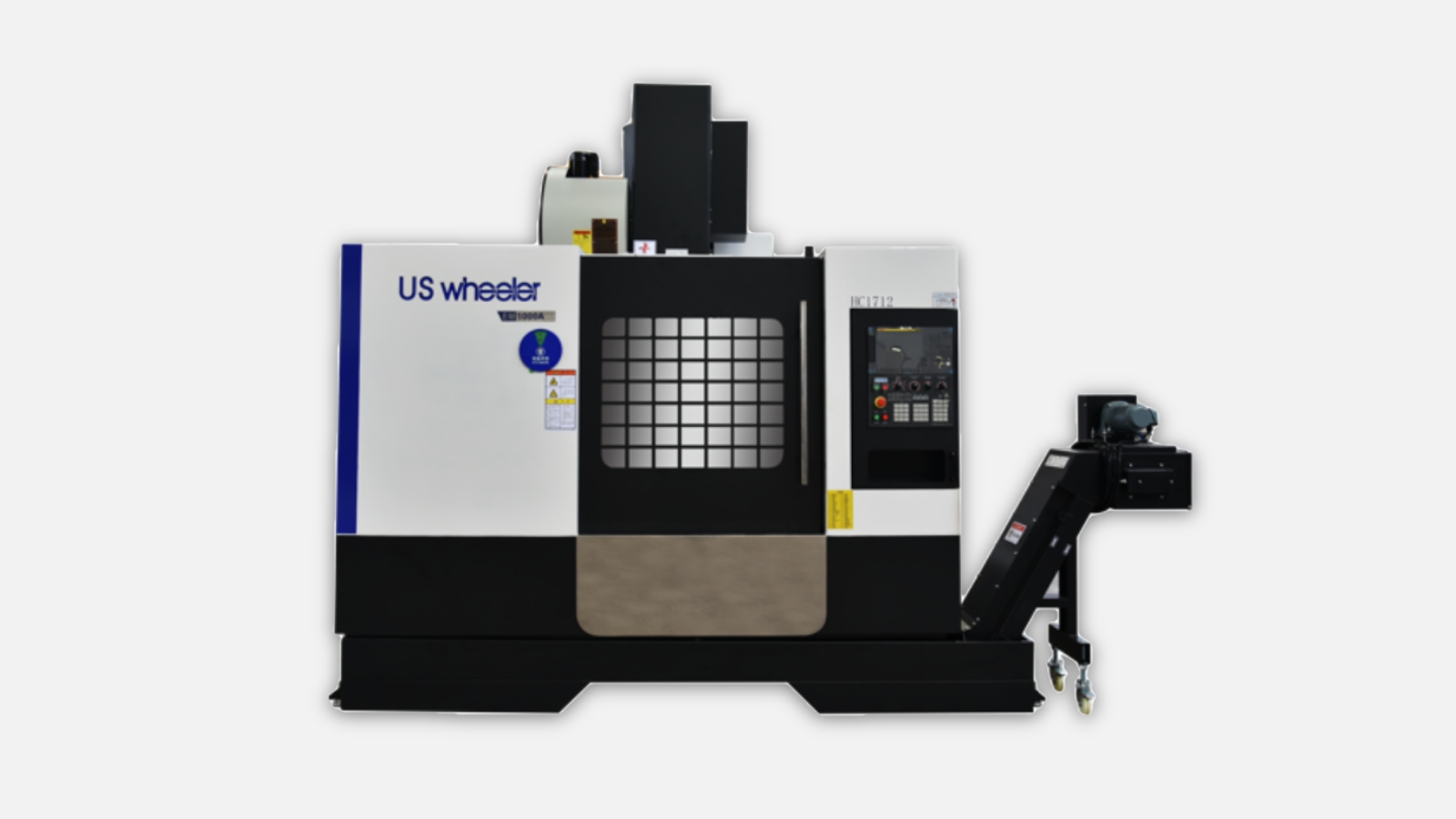

Vertical 3-Axis Milling Center EM1000A.

EM1000A is a milling machine manufactured by the Chinese company US WHEELER. It is designed for processing various materials, including metals, wood, plastic, and others. This machine is an excellent choice for producing components, machine parts, prototypes, and other products.

The EM1000A is equipped with a special controller that ensures high precision and reliability in processing. The machine also features a wide range of speeds, allowing it to work with different materials and perform a variety of tasks. It is capable of operating in both automatic and manual modes, making it user-friendly.

The EM1000A offers high performance and efficiency. It is equipped with a powerful motor that provides high speed and accuracy in processing. The machine also has a large working table, enabling it to handle large parts.

The EM1000A is easy to use and maintain. It comes with an operating manual that contains detailed information on its installation, setup, and usage. Additionally, the machine has a simple design, which facilitates maintenance and repairs.

Overall, the EM1000A is a high-precision, reliable, and efficient milling machine that is an excellent choice for various material processing tasks. It ensures high accuracy and performance, is easy to use and maintain, making it an ideal choice for producing components, machine parts, prototypes, and other products.