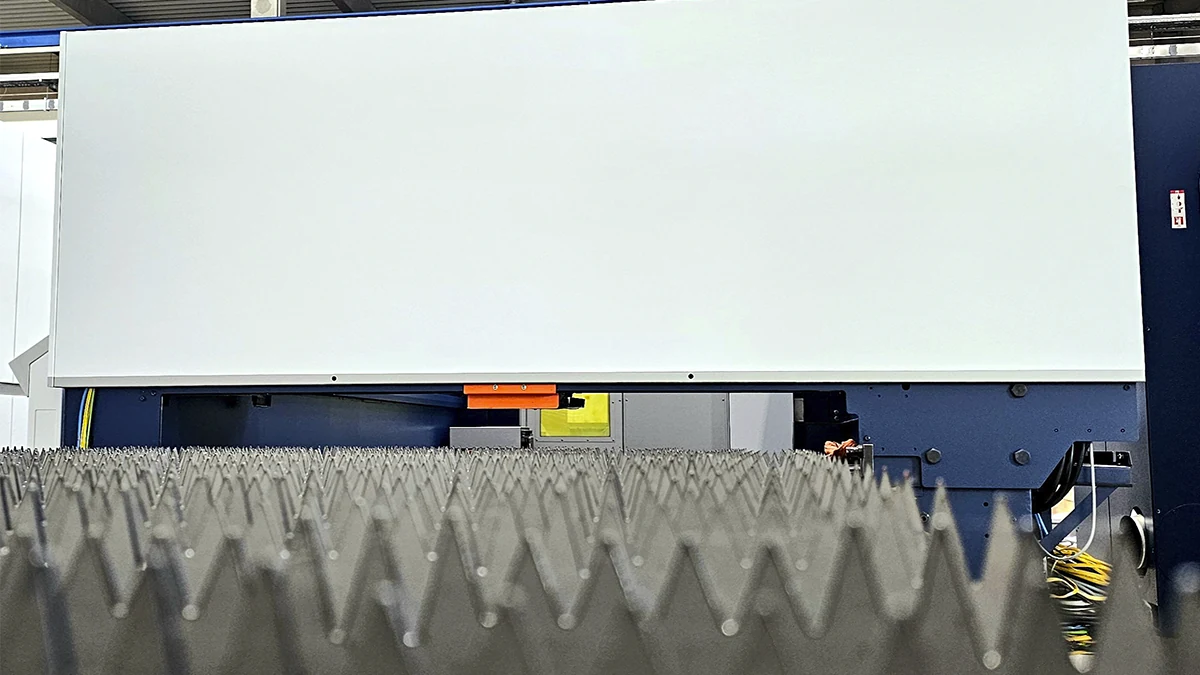

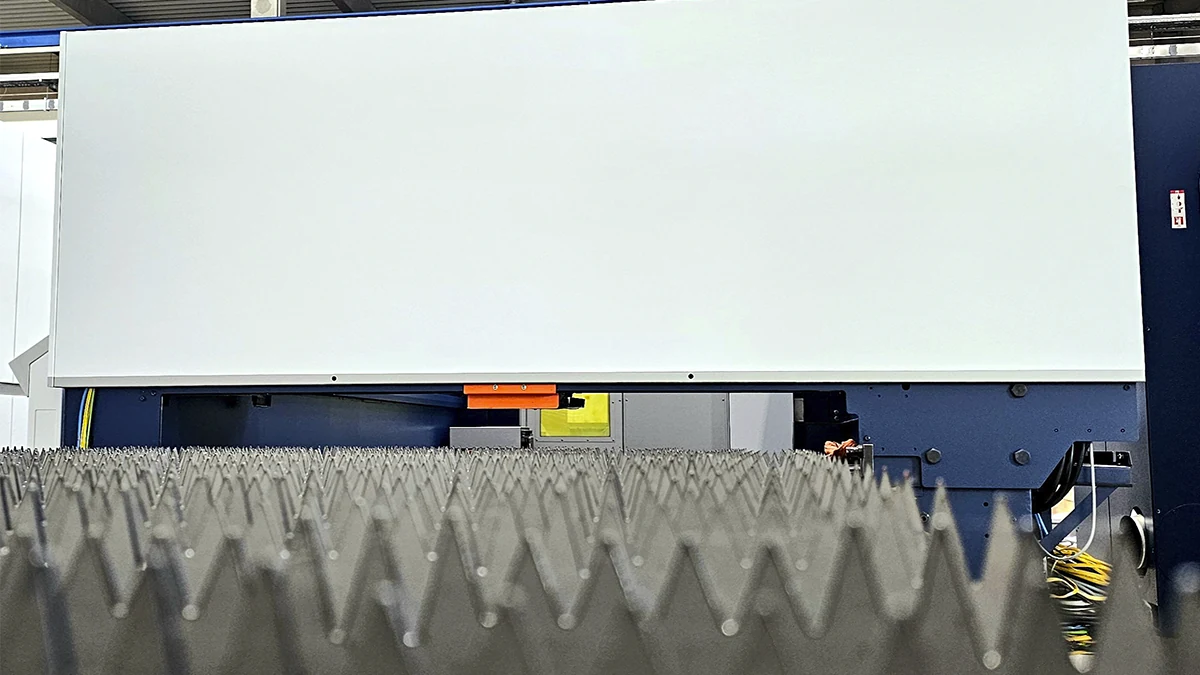

Refurbished TruLaser 3030 fiber (L492) 4 kW cutter, 3×1.5 m bed, low hours.

TRUMPF has been delivering fiber-laser sheet cutters for more than 30 years, and the TruLaser 3030 fiber platform alone has gone through five major hardware revisions. The refurbished unit offered here carries the factory designation L492 and delivers a steady 4000-watt beam via the well-known TruFiber resonator. With only 49.177 total hours and 36.364 laser-on hours, it still sits far below the service-life threshold quoted by TRUMPF service bulletins.

Before getting into the details, it helps to picture the day-to-day reality on a European job shop floor. Operators want fast change-overs, maintenance technicians expect straightforward access, and production managers focus on cost per part. This text follows that line of thought.

The key data points often checked by production managers are summarized below.

Each of those bullets is confirmed both by the official TRUMPF specification sheet and by field reports from users on the German-language CNC-Zone forum dated February 2023.

The following table sets those figures next to two popular alternatives, offering a quick visual cue:

| Parameter | TruLaser 3030 L492 | Bystronic BySprint PRO 4020 | Salvagnini L3-30 |

|---|---|---|---|

| Laser power | 4 kW | 4.4 kW | 4 kW |

| Rapid traverse | 140 m/min | 120 m/min | 170 m/min |

| Positioning accuracy | ±0.1 mm | ±0.15 mm | ±0.12 mm |

| Mild-steel max | 20 mm | 20 mm | 18 mm |

| Footprint | 9 m² | 11 m² | 10 m² |

Even though the Salvagnini runs faster on paper, user feedback in SheetmetalWorld Group points out that real-world cycle times even out once part sorting and pierce stabilization are included.

Users who normally cut below 10 mm find the 4 kW source more than adequate, yet the machine will reliably go up to 20 mm mild steel. Stainless and aluminium plateau at 15 mm for quality grade 2 edges. Thicker sheets require edge conditioning, but that is common in this power range.

These figures stem from a field test carried out by the Dutch reseller ASK-Metal during autumn 2022. They cut 8 different alloys over a two-day demo and published the raw data on LinkedIn.

Margin calculations often overlook auxiliary gas consumption. A TRUMPF Application Note from June 2021 quotes typical nitrogen flow of 700 l/min at 12 bar for 10 mm stainless. That is roughly 15 % lower than on comparable CO₂ machines, which explains why quite a few workshops replace two CO₂ tables with a single fiber.

Refurbished units seldom arrive with full automation, yet the L492’s interface rack already supports:

The OEM software license for TruTops Fab is transferred to the new owner free of charge according to TRUMPF circular 12/20. Integrating MES or ERP is a routine job, as the controller speaks OPC-UA out of the box.

Machine buyers usually look at Bystronic and Prima Power in the same shortlist. Three main points make the TruLaser the safer bet:

Those differences might appear small on paper, yet downtime studies by the Fraunhofer IPT (Report FV-21-07) show that mirror cleaning accounts for 18 h of lost production per year on average.

Because this unit is refurbished, the laser source already went through a factory acceptance test that included:

The cooling unit and dust collection system passed leak-rate checks as well. Maintenance logs dated April 2024 are available in PDF.

After installation, daily upkeep takes less than 10 min. Monthly tasks are limited to filter swap and light lubrication. The service menu reminds the operator of every upcoming interval in plain text, avoiding cryptic code numbers.

Let us run a concise calculation. Cutting 6 mm mild steel sheets at 3 m/min with 2 h setup per week yields roughly 40 h of net cutting time. At an electricity tariff of 0.18 €/kWh, the machine pulls about 16 kW during cutting and 6 kW idle. That equals an average weekly cost of 132 €, excluding gas. Assuming a shop rate of 80 € per hour and a selling price of 0.65 € per cutting meter, payback sits comfortably under 18 months for a single-shift operation.

On the UK-based forum MyLaserShop, owner “SheetKing” wrote in January 2024:

“Switching from our old CO₂ to the 3030 fiber dropped our part cost by 22 % and freed floor space for a press brake.”

A similar comment from Italian job shop MetalToscana mentions achieving clean kerfs in 4 mm aluminium without thick oxide, reducing secondary deburr work by roughly 45 minutes per batch.

In day-to-day production the TruLaser 3030 fiber offers a straightforward recipe: fast axes, steady 4 kW beam, and readily available service. Companies that cut varied material thicknesses in small-to-medium series value the quick switch-over and low assist-gas bills. That combination explains why sheet-metal subcontractors and machine builders make up the bulk of buyers for this model.

Summing up, the refurbished L492 delivers TRUMPF build quality at a pre-owned price tag, letting workshops expand capacity without stretching capital budgets.