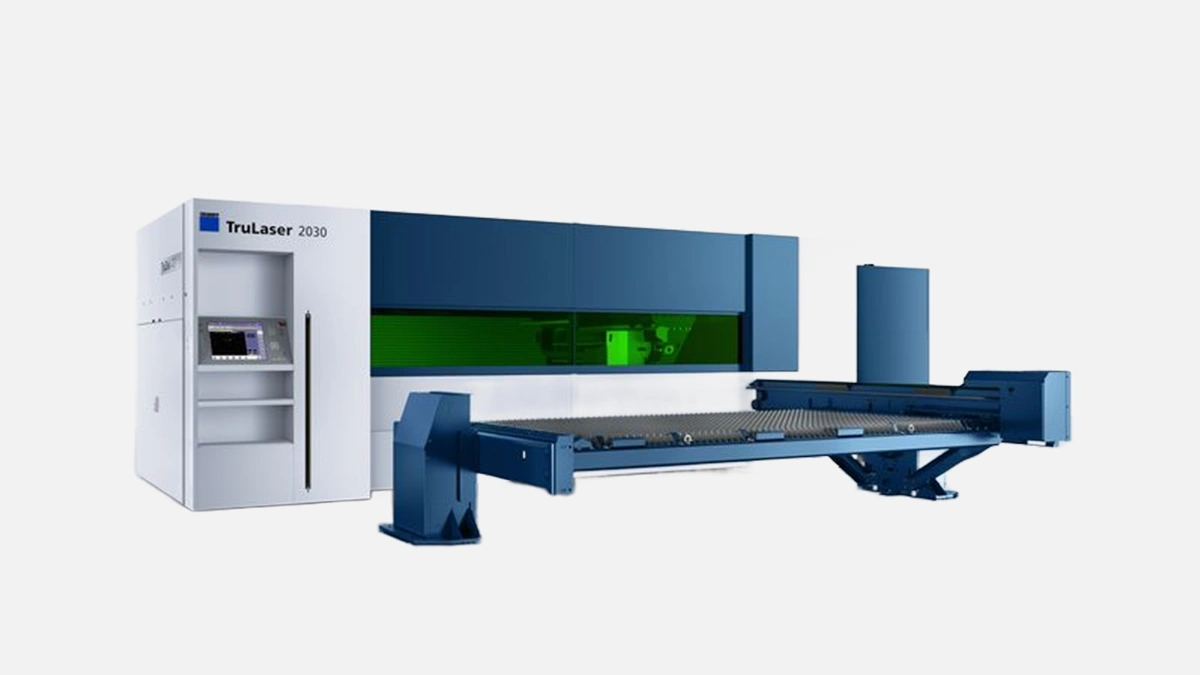

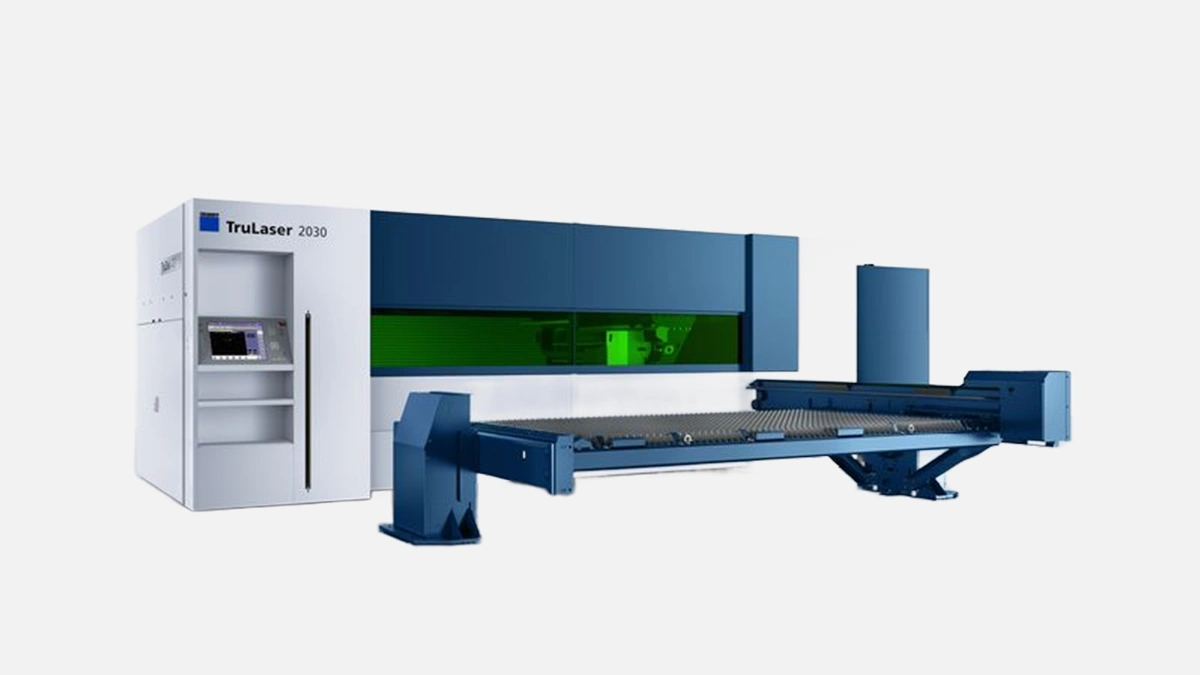

Trumpf TruLaser 2030 fiber cuts 3000×1500 mm sheets up to 20 mm thick with 4 kW power, ideal for UAE job shops.

Short burst first. Fast cut, bright sparks, crew smiles. Then, suddenly, I realise how much sheet the thing chews through in a single shift and I start counting cost per part in my head, it gets messy but the numbers are on my side, so I calm down.

A lot of UAE job shops still babysit CO₂ units from the late 2000s. They complain about mirrors fogging, gas bills climbing, the whole drama. Drop a TruLaser 2030 fiber in that same bay and, boom, nitrogen savings show up, uptime jumps, operators stop chasing alignment. Not magic, just a solid bit of German engineering history, 100+ years of sheet-metal know-how packed into a cabinet roughly the size of two SUVs parked nose to nose.

Now, hold on, I am not saying every shop in Sharjah must swap its entire fleet tonight. Some projects live fine on the old rigs. But if parts are getting thinner, lead times shorter, and energy prices… well, you read the news… a fiber source starts looking like the safe bet.

Trumpf keeps the feature list chunky, almost too chunky, so I will cherry-pick. The machine bed is welded, stress relieved, then milled in a single clamping, helps the frame stay flat when the desert heat swings from 20 to 45 °C between night and noon. The TruDisk resonator sits under the side cover, fiber length tuned at the factory, minimal back-reflection, that is handy when someone wants to cut shiny Cu.

Before diving into the next bit, a quick list is overdue.

Three strokes above, done. Notice how none of that is fluff, every bullet is an operator headache fixed. Moving on.

People keep asking, can it cut duplex, can it cut brass, what about chequer plate, the list never ends. The boring answer, yes, as long as specs below hold. The interesting part is edge quality. On brass at 6 mm the kerf walls come out almost mirror smooth, no secondary machining needed on decorative panels used in hotel lobbies along Sheikh Zayed Road.

Below is a tidy table. Stare at it, argue with it, then get back to production.

| Material | Max thickness | Typical assist gas | Edge roughness Ra |

|---|---|---|---|

| Mild steel | 20 mm | Oxygen / Nitrogen | 12 µm |

| Stainless 304 | 15 mm | Nitrogen | 10 µm |

| Aluminium 5083 | 15 mm | Nitrogen | 14 µm |

| Brass | 6 mm | Nitrogen | 9 µm |

| Copper | 6 mm | Oxygen | 11 µm |

Cool, table done. The takeaway, one setup covers most daily alloys found in HVAC ducts, electrical cabinets, food-grade enclosures.

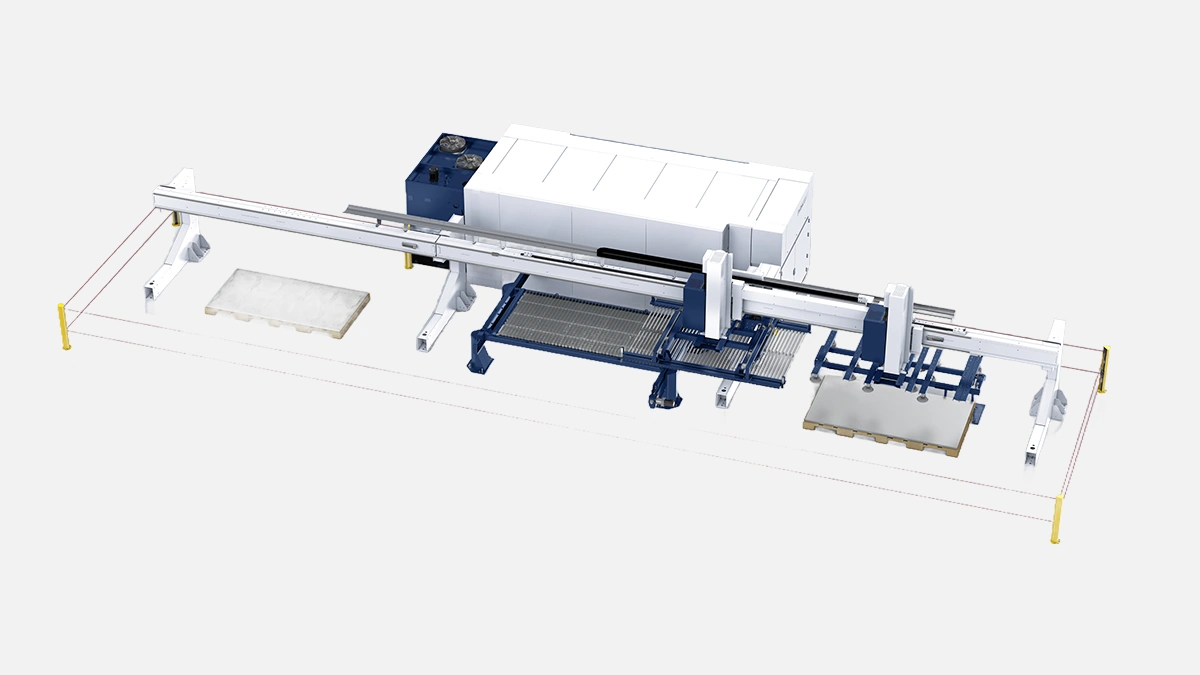

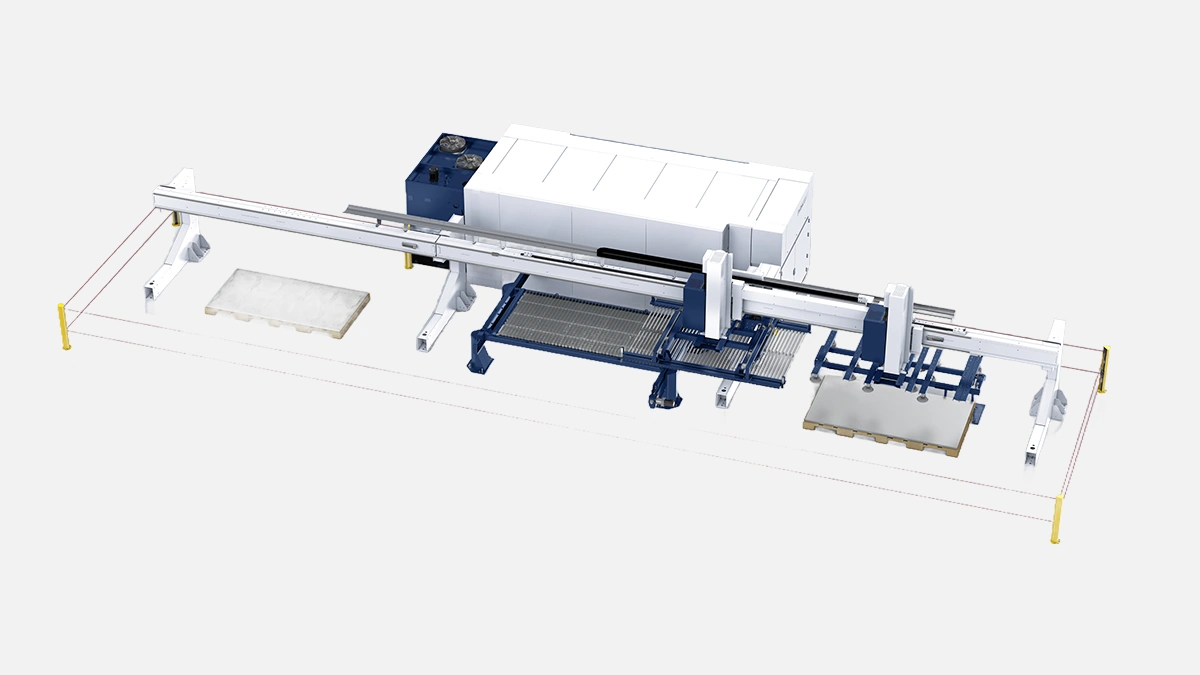

Trumpf sells the 2030 fiber in a vanilla form, then stacks modules on top. LoadMaster Compact is the usual first add-on, it handles blanks up to 25 kg each, great for thin stainless runs at kitchen equipment plants in Ajman. If throughput spikes, you bolt on the SortMaster to pick parts and drop them into bins, fully lights-out, nobody sweats the night shift.

Another bullet set feels right here.

Those gadgets add cost, yes, but they make sense when running 10,000+ parts a month.

Time to call out the neighbors. Bystronic ByStar Fiber 3015 with a 4.4 kW source posts similar thickness numbers but tends to stall on high-reflect materials unless you upgrade optics. Amada ENSIS 3015 RI carries clever variable beam tech, yet its shuttle changer is slower, roughly 30 seconds cycle. Mazak Optiplex Nexus FIBER looks good on paper, still, users on the Abu Dhabi forum complain about service wait times. Against that backdrop the TruLaser 2030 fiber brings two strong cards, the local Trumpf service hub in Dubai Investment Park and the fact the machine shares spare parts with bigger 5030/5040 cousins, so no exotic inventory.

You might wonder, why 2030 not 3030. The number game is simple, 20 denotes entry class, 30 stands for work area 3000 mm long, and “fiber” tells the laser source. Same chassis grew through three revisions, Rev A back in 2016, Rev B in 2019, current Rev C landed late 2022 adding the louvered side doors and updated TruDisk 4001. Cutting performance bumped maybe 8 %, nothing earth-shattering, but coolant routing got far cleaner.

On a mixed nesting plate for elevator brackets, 3 mm mild steel, the shop in Ras Al Khaimah clocks 29 parts per minute net, including table swap, using two nozzles. They feed parts into a TruBend 5130, cycle keeps up fine, no bottle-neck. Energy log shows 7.8 kWh average load, cheaper than running the old CO₂ at idle.

Daily checklist is short, wipe lens window, drain condensate trap, top up nitrogen filter. Weekly you grease linear rails, Trumpf even prints QR codes on the covers that pull up a how-to video when scanned with a phone, nice touch for new hires who panic at the hint of Zerk fittings.

I see three clusters. Sheet-metal subcontractors who do everything from sign boards to machine guards, HVAC duct makers that used to rely on plasma, and OEMs building enclosures for solar inverters. They all need predictable cut, small heat zone, and they hate spending half a day aligning mirrors. This machine ticks those boxes, no drama.

Not flawless. Table footprint asks for decent real estate, and the initial buy-in is nothing light. Yet, when tonnage climbs and deadlines tighten, the payback math looks honest. That is why many Gulf workshops trade in two ageing CO₂ units for one 2030 fiber, keep staff count flat, double shipped volume, everyone happy.

Steady frame, crisp edge, grown-up service network, simple UI, low running gas. That is the package, take it or leave it.